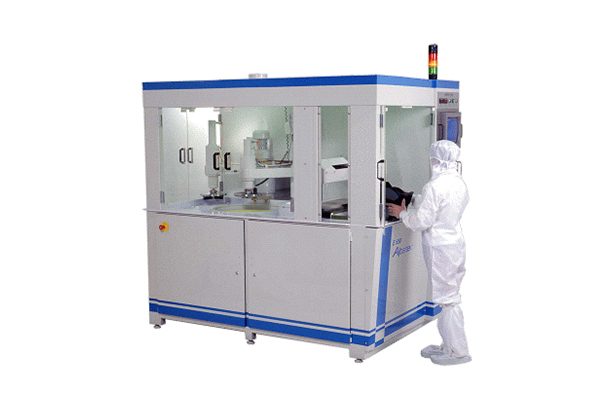

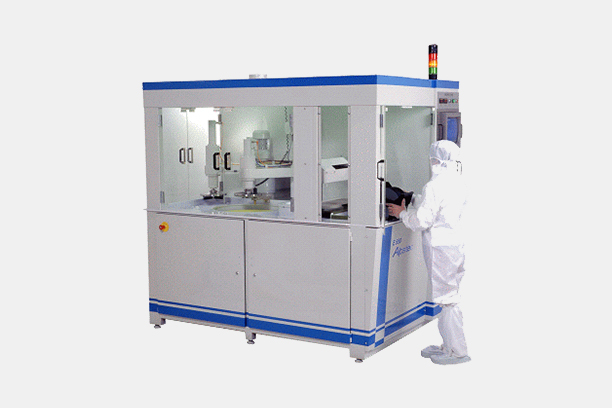

Front side :

The control screen is located in front of the user, on the right, on the left side buttons for loading and unloading and water switch for rinsing the wafer just after process.

A usb connector is placed there for saving , or down loading recipes or process data.

For easy access the slurry pumps are integrated on the back, enabling a convenient hook up for slurry supply.

Control cabinet :

All the elements are integrated inside the tool. Nothing except slurry tanks is outside

Back side :

Connection to facilities is located on the back side of the tool. Interface to lab network is also placed on the back side

The stainless steel carrier is designed for vacuum and back pressure functions.

The carrier is equipped with a Delrin retaining-ring. The wafer is held by vacuum and is protected by poromeric pads on the rear.

Adjustable process parameters, each step includes

– Slurry flow rates (up to 2 slurries)

– Head and platen speed and direction

– Down force

– Back pressure

– Duration

– sweeping area

– Real time parameters display

– Soft transition from step to step

The E400 E machine is a new tool. Its development is based on the 15 years of experience of Alpsitec in the field of CMP and tool control.

Like for our other tools, specific designs can be realized to respond to customers’ demands that cannot be satisfied with the existing solutions.

The tool control offers the same characteristics as those of our bigger tools:

-External polishing recipe edition possibility

-10 process steps

-In situ conditioning activated or not at each step (under development)

-Possibility to raise the carrier during the process for conditioning while the product is not on the polishing pad

-Sweeping range defined for each step

-Soft transition of process parameters between each step and its following one

-Various technologies carriers:

-mono wafers or multi wafers,

-standard or low pressure version,

-Wax, template or insert mounting

-Various conditioning tool types

-Quick exchange of parts dedicated to process : platen, carrier and conditioning head (time required 2min).

-Perfect for sharing the machine between various teams and running various processes with different consumables

-A compact tool: a table top tool.

The goal of that tool is to propose a real CMP tool for small samples.