Industrial furnace manufacturer, ICBP, Carburizing furnaces, Vacuum furnaces, Induction furnaces and melting

ECM, FURNACE MANUFACTURER FOR MATERIALS AND LABORATORIES

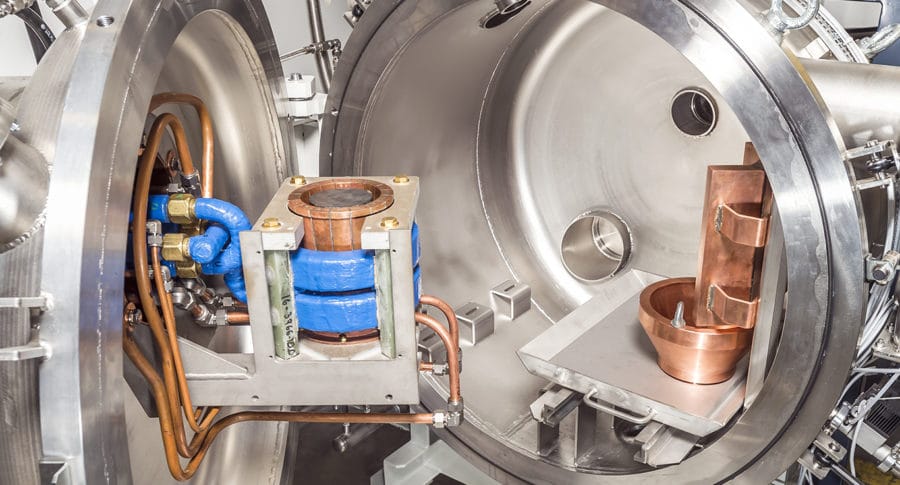

The induction melting furnace from ECM Technologies has been adapted to reduced treatment volumes. Enjoy the latest technologies for melting metal alloys, glasses, silica and other oxidizing materials requiring high temperature ranges.

PLUS AND BENEFITS

This furnace has been designed for laboratories and R&D centres, but is also adapted to industrial use for small production. Thanks to its compact design, it allows the elaboration of materials for volumes from 0,03L to 10L, corresponding to loads from 0,2Kg up to 80Kg.

Its compact design does not impact its versatility. Indeed, as well as the VIM furnace, the laboratory furnace allows you to treat titanium, aluminium, steel and zirconium. Other materials can be treated on demand, such as oxides or other refractory materials.

The laboratory furnace has been designed to melt alloys and metals with working temperatures comprised between 750°C and 3000°C.

Also, this furnace is modular and scalable according to the needs of each client. Technical expertise from ECM Technologies allows us to support customers with tailor-made technical solutions matching their needs.

Finally, the evolutionary configuration of the furnace allows to follow investment programs of laboratories, and to adapt the installation according to resources and needs.

POSSIBLE APPLICATIONS

- Melting / Re Melting

- Vitrification

- Purification

- Recycling

- Atomising

EFFECTIVE DIMENSIONS

| TREATMENT CAPACITY | ||

| MATÉRIALS | LOAD | VOLUME |

| TITANIUM | 0.2 TO 80 KG | 0.03 TO 10L |

| ALUMINIUM | ||

| STEEL |

Heating up to 1050°C standard, high temperature available

MORE SIZES AVAILABLE : CONTACT US

OPTIONS

- Hot crucible: refractory, ceramic, tungsten, molybdenum, graphite, platinum

- Cold crucible: copper, stainless steel

- Bottom pouring

- Tilt pouring

- Leading edge instrumentation: pyrometer, cameras, monitoring

- Multi sampling

- Oxygen measurement within the melt

- Bubbling control

- In line integration

- Adding additive

- Sand mould, ceramic mould or metallic mould

- Customization according to needs