Index drive, CAM, Roller gear type reducer

Dynastation DSR series is kind of Servo-Motor Reducer, It is ideal for condition which is need highload capacity & high precision. (Max. 20Ton available loaded.)

Huge thru hole on output axis provides easier wiring and piping to the table top devices. Super flat design and huge thru hole allows operator an easier work handing.

Characteristics of the product

|

Barrel Cam Structure - Realize High precision and rigidity With DSR series originally developed roller reducer mechanism, both robustness and high accuracy is achieved. Higher servo gain can be applied, and it contributes to quicker positioning time. |

|

Large thru hole and super flat design DSR series, Compared to other similar products, it has the lowest height. It allows operator an easier work handing. |

|

Additional gear reducer system he DSR series is integrated additional reducer system into the product itself. You can adjust the required number of cycles, with a relatively small capacity of a servo motor. It gives you high power output. |

|

Direct contact bearing Self-developed 4 point contact bearing, realized high rigidity and maintenance free, As a characteristics of 4 point direct contact type bearing, The precision of fabricated track surface is directly reflected to the output performance. It achieves the best performance in terms of roundness, shaking, and flatness during rotating |

| Items | DSR120 | DSR160 | DSR220 | DSR300 | DSR400 | DSR500 |

|---|---|---|---|---|---|---|

| ALLOWABLE MAX LOAD | 2,000kg | 3,000kg | 7,500kg | 10,000kg | 15,000kg | 20,000kg |

| SPIRAL TABLE HEIGHT | 175mm | 205mm | 225mm | 250mm | 280mm | 340mm |

| Spiral Table Diameter | Φ290mm | Φ375mm | Φ500mm | Φ700mm | Φ900mm | Φ1,136mm |

| Output Hollow Diameter | Φ130mm | Φ180mm | Φ255mm | Φ380mm | Φ500mm | Φ630mm |

| Recommended Servo Capacity | 1.5kW | 2.0kW | 3.5kW | 7.5kW | 11.5kW | 15.0kW |

| Standard Reduction gear ratio | 1/100 | 1/120 | 1/120 | 1/120 | 1/180 | 1/225 |

| Repeatability | 0.05mm(r=1,000mm) | |||||

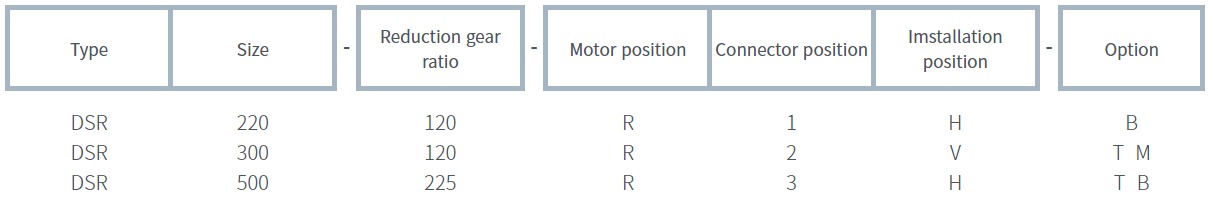

Code Table

| Type | Size | Reduction gear ratio | |

|---|---|---|---|

| DSR | 120 | 100 | lease contact us for non-standard reduction gear ratio other than chart on the left. |

| 160 | 120 | ||

| 220 | 120 | ||

| 300 | 120 | ||

| 400 | 180 | ||

| 500 | 225 | ||

| Motor Position | Connector Position | ||

|

R(Right) Recommended standard position |

L(Left) |

1 Inner side of Body |

2 Front side of Body |

|

3 Output side |

4 Bottom side of Body |

||

| Installation position | Option | ||

|

H Plane position |

V Column position ※DSR500 is exclusive model for plane position. |

T 2 pin holes on output table side. |

B 2 pin holes on housing |

|

Z Other Setting of output as facing downward is not possible due to function of Oil-seal. |

M 4 mounts for column position. ※T Nut bolt is not included. |

||

Example of usage

|

Welding process 180degree rotation |

Forming molds ouput accuracy |

Assembly process vertical index |