Korea’s top class Flow and Level Instruments manufacturer with 45 years of history

Overview

The measurement principle is based on the differential pressure that is generated between the upstream side and throat of nozzle, and the flow rate can be determined by the measured differential pressure value.

Flow Nozzle is costlier than orifice due to their construction but it is suitable to measure the flow rate of fluid flowing at high temperature and pressure. Under the same measurement condition, the flow nozzle has a higher mechanical strength, can permit the flow of more than 60 percent greater volume of a fluid, and can measure the flow rate of fluid which contains solid particles with less disturbance than an orifice which has the same bore.

Calibration and Discharge Coefficient Determination

All of HFN Series that is manufactured and supplied by Hitrol is calibrated with water at our liquid flow calibration system to determine the Discharge Coefficient (Cd) to verify the performance of the flow meter.

Discharge Coefficient

Long radius Nozzle manufactured in compliance with ISO-5167 and supplied with pipe wall taps have a discharge coefficient that is characterized by the equation below;

C = 0.9965-0.00653

The lap calibration presented below is a sample of wall taps assembly.

Specification

Pressure Taps Orientation

Nozzle Types

ISO 5167

HITROL manufactures and supplies all flow nozzle type as per in full compliance with ISO-5167 standard and there are two types of long radius nozzle in ISO-5167 standard, one is a High Ratio Nozzle and other is a Low Ratio Nozzle, and they can be designed with a ß-Value between 0.2 and 0.8 and it complies with ISA 1932 Nozzle and Venturi-Nozzle. Flow Nozzle is suitable to determine the flow rate of fluid at high temperature and pressure. Also it can measure the flow rate of fluid containing a little amount of solid particles.

ASME MFC-3M

HITROL supplies flow nozzle types as per in full compliance with ASME standard, high and low ß nozzles in ASME MFC-3M and low ß nozzle with throat tap in ASME PTC 6.

Flanged Type Flow Nozzle

Flanged Type Flow Nozzle is used for insertion between piping flanges, where frequent maintenance is required in the line, and is designed in accordance with ISO 5167 and ASME MFC-3M.

Weld-in Type Flow Nozzle

Weld-in Type Flow Nozzle is used where flanges are not applicable such as high temperature and pressure applications. Unless otherwise specified, HITROL offers this type as standard.

Holding Ring Type Flow Nozzle

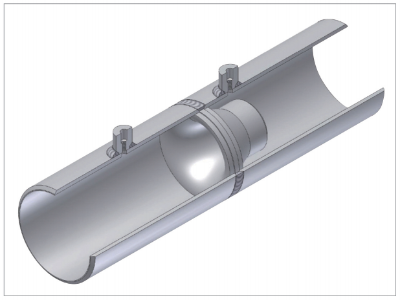

Holding Ring Type Flow Nozzle is usually designed to be installed in pipes without flanges and it is mounted with the assistance of holding ring and pins that are made of same materials as pipe to avoid a welding of dissimilar materials.

Knock-pin Type Flow Nozzle

Knock-pin Type Flow Nozzle also eliminates welding of dissimilar materials, just like holding ring types do. The only difference is that it is usually more difficult to assemble this nozzle to piping.

Required Straight Pipe Length

■ Values expressed as multiples of internal diameter, D