This product is manufactured by

HITROL

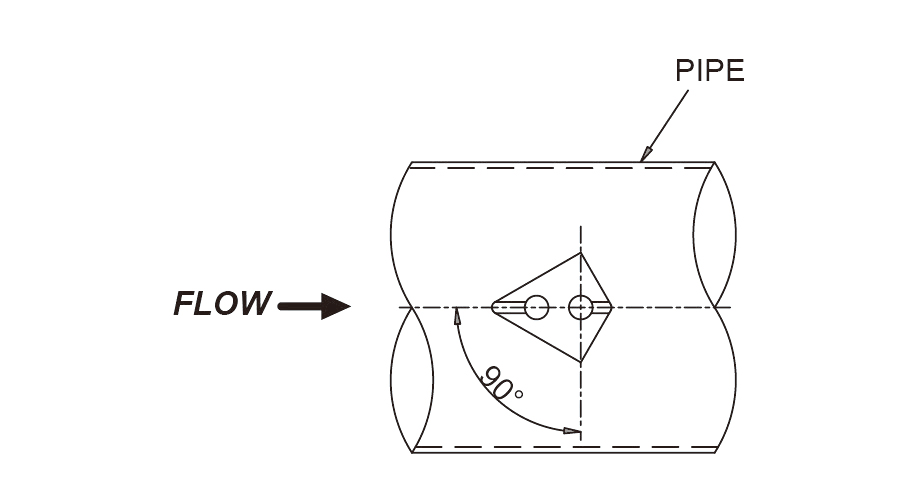

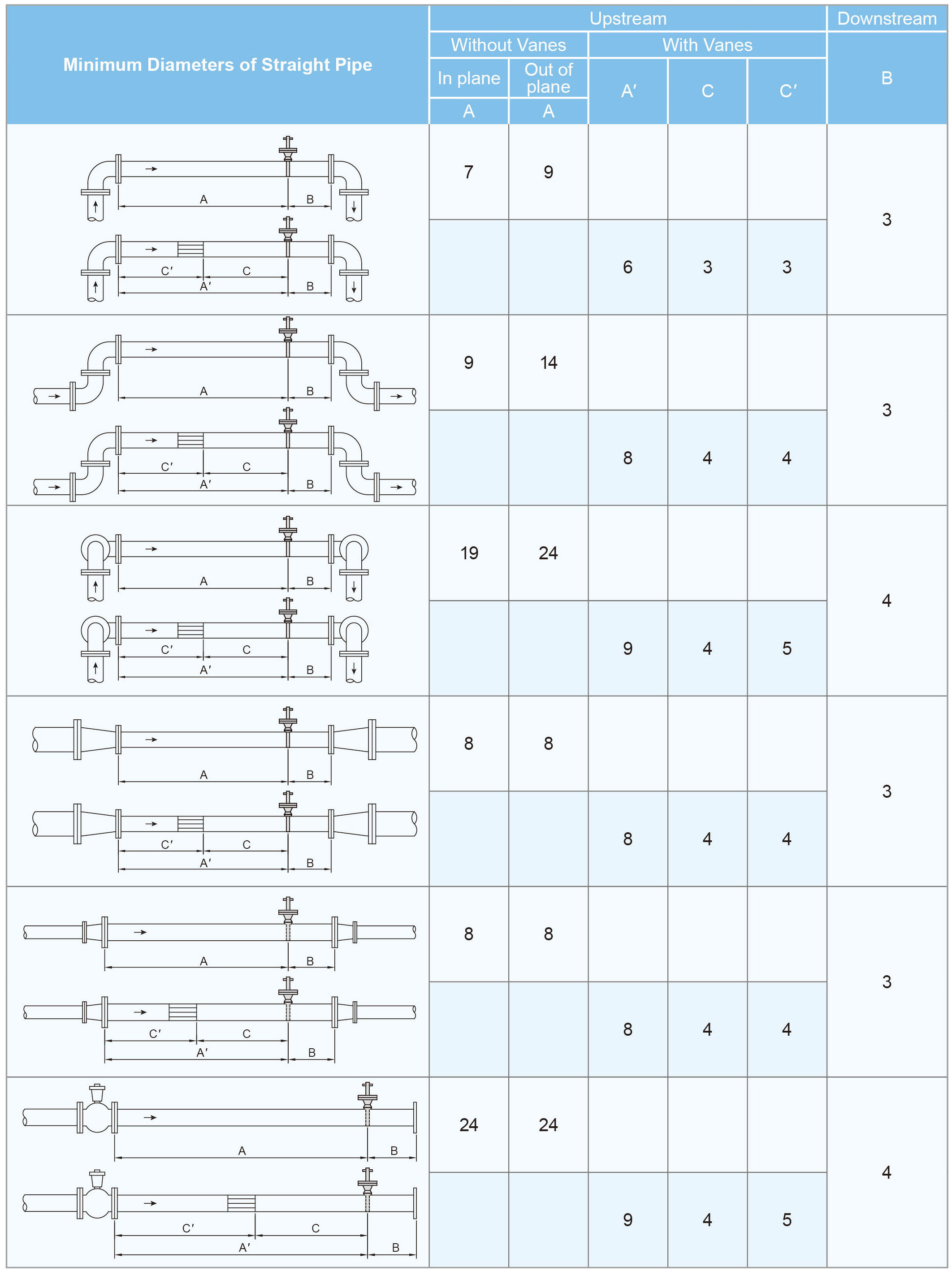

Averaging Pitot Tube

Model Name

HAPT Series

Manufacturer information

HITROL

Verified & Trusted Manufacturer

Korea’s top class Flow and Level Instruments manufacturer with 45 years of history

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

HITROL

Product Type

Machine

Brand

-

SKU

130023

Product Name

Averaging Pitot Tube

Model Name

HAPT Series

Size

-

Weight

-

Product Details

More products

Float Type Level TransmitterHT-100R Series, HT-100RS, HT-100RSH, HT-100RS-Ex, HT-100RSH-Ex, HT-100RV, HT-100RV-Ex, HT-100RT, HT-100RTH, HT-100RT-Ex, HT-100RTH-Ex

Magnetic Flap Level GaugeHLG-100F Series, HLG-100F, HLG-100FT, HLG-100FS

Tank Level GaugeHLT-1000 Series, HLT-1110, HLT-1210, HLT-1112

Vibration Type Level SwitchHTM-30N Series, HTM-30N, HTM-30N-Ex

Vibration Type Level SwitchHTM-20N Series, HTM-20N-A, HTM-20NH-A, HTM-20N-B, HTM-20NH-B, HTM-20N-C, HPV-20N-A, HPV-20NH-A, HPV-20N-B, HPV-20NH-B

Float Type Level SwitchHM-95 Series, HM-95, HM-95-Ex, HM-95H, HM-95H-Ex, HM-95V, HM-95V-Ex, HM-95VH, HM-95VH-Ex

Venturi TubeHVT Series

Flow NozzleHFN Series

Vibration Type Level SwitchHTM-930 Series, HTM-930, HLC-901L, HLC-901P

Radio Frequency Type Level SwitchHCC-96RF Series, HCC-96RF-C, HCC-96RF-CH, HCC-96RF-S, HCC-96RF-R, HCC-96RF-RH, HPC-96RF-R, HLC-96RF-R, HLC-96RF-RA

Capacitance Type Level SwitchHCC-95P Series, HCC-95P, HCC-95PW, HCC-95PH, HCC-95PWH, HCC-95P-Ex, HCC-95PW-Ex, HCC-95PH-Ex, HCC-95PWH-Ex, HPC-95P, HPC-95PW, HPC-95PH, HPC-95PWH

Float Type Level SwitchHM-12(10) Series, HM-10, HM-12S, HM-12H, HM-12H-Ex, HM-12D, HM-12H-SP, HM-12H-SP-Ex, HM-12H-L, HM-12H-L-Ex

Displacer Type Level SwitchHM-90(30) Series, HM-90, HM-90-Ex, HM-90H, HM-90H-Ex, HM-30

Float Type Level SwitchHR-30 Series, HR-30S, HR-30SH, HR-30S-Ex, HR-30SH-Ex, HR-30C, HR-30CH, HR-30C-Ex, HR-30CH-Ex, HR-30V, HR-30V-Ex, HR-30T, HR-30TH, HR-30T-Ex, HR-30TH-Ex

Capacitance Type Level TransmitterHT-100CT Series, HT-100CT, HT-100CTH, HT-100CTW, HT-100CTWH, HT-100CT-2, HT-100CTH-2, HT-100CTW-2, HT-100CTWH-2

1/4

Measurement Principle

Measurement Principle