Printing Press Manufacturer, Printing, Converting, FLEXOGRAPHIC Solutions, ROTOGRAVURE Solutions and more

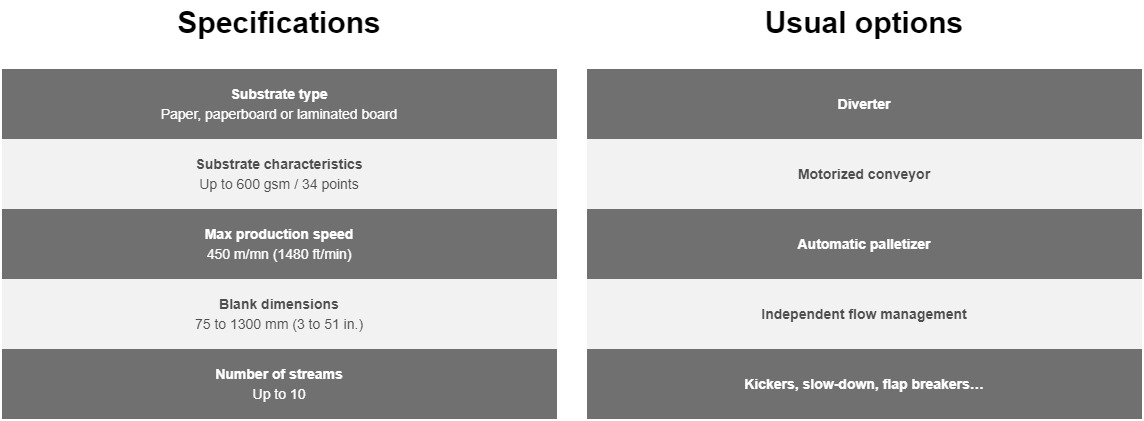

Manage blanks at high speeds, whatever their layout and dimensions or cardboard specifications.

Komori-Chambon designs and manufactures tailor-made solutions from A to Z: transfer, spreader, shingling and stacking.

Deliver 100% good blanks with an optional diverter coupled with an optical inspection device.

Optimize your production with automated palletization systems as option.

Komori-Chambon advantages :

- Maximum control and customizable delivery parameters (number of blanks, pile height) up to 450 m/mn

- Independent streams management and optional independent lifts (Multilift system) combined with diverter

- Custom design by application and blank characteristics thanks to longstanding experience

- Flexible configuration (inline installation after Komori-Chambon or OEM die-cutter / offline after platen die-cutter…)

Main Applications

General Folding, Liquid packaging, Tobacco, Pharma / Cosmetics

Komori-Chambon expertise

|

Comprehensive know-how Komori-Chambon designs taylormade solutions for each delivery step. We provide either full delivery sections or separated modules which we integrate into your production line. |

|

High speed production 450 m/mn is the new speed standard defined by Komori-Chambon, with flawless stacks ready to ship. Boost your productivity. |

|

Extreme versatility Heat not Burn blanks, bricks or pizza boxes : Komori-Chambon gathered a long experience allowing a total control whatever the blank type. |

|

Maximum output Our delivery solutions are designed for an intensive use 365 days per year. The optional palletizers will allow you to further push the limits. |

Production flow insights

|

▼ |

- The blanks which have just been cut and stripped are separated longitudinally. In liquid packaging applications, the blanks are partially cut and separated by the transfer module - They are transfered from the rotary die-cutter to the spreader for the next steps - Depending on the application, the transfer module can integrate various equipments such as flap breakers, vacuum belts or a non-overlapping configuration. |

|

|

▼ |

- The blanks are separated transversely by the spreader and are guided into parallel flows - The spreader also allows the sorting and the evacuation of faulty blanks thanks to a 2-way blanks management. - The stacker is then managed bycan handle individual flows (up to 10) - Several configurations are available for an efficient control of any type of blank (kickers, slow-down function…) |

|

|

▼ |

- The ejected blanks form a shingle along each flow on a first conveyor - The blanks are counted and precisely handled according to adjustable parameters defined for the shingle (gap between blanks) - The progress of each shingle is controlled along the second conveyor according to the stack creation and evacuation |

|

|

|

- The blanks are dropped at the end of the second conveyor into the stacker - Jogger bars ensure neat stacks - When the stack is complete (complying with the predefined number of blanks and height), it is pulled down by the lift and evacuated onto the final conveyer belt - The next shingle which was put on hold on the second conveyor is then released for the next stack. |

Available configurations

|

INLINE In a full inline configuration, the delivery is installed right after the rotary die-cutter following itself the printing section. This configuration allows the highest productivity, without any flow interruption. The delivery solution can be installed as a whole, or split in various modules (transfer or stacker only). The installation can be realized after OEM equipment.

|

|

OFFLINE The Komori-Chambon delivery modules can be installed offline after a rotary die-cutter or a web platen. |