Multidiscipline Simulation Software Supplier, Linear and Nonlinear Finite Element Analysis (FEA), Control Systems Simulation and more

Real Dynamics for Vehicle Design and Testing

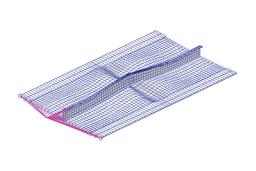

With Adams Car vertical products, engineering teams can quickly build and test functional virtual prototypes of complete vehicles and vehicle subsystems. Working in the Adams vehicle vertical environment, automotive engineering teams can exercise their vehicle designs under various road conditions, performing the same tests they normally run in a test lab or on a test track, but in a fraction of time.

- Analysis of suspension, steering and full-vehicle maneuvers

- Easy integration of control systems into vehicle models

- Creation or import of component geometry in wireframe or 3D solids

- Extensive library of joints and constraints to define part connectivity

- Model refinement with part flexibility, automatic control systems, joint friction and slip, hydraulic and pneumatic actuators, and parametric design relationships

- Comprehensive linear and nonlinear results for complex, large-motion designs

- Comprehensive and easy to use contact capabilities supporting 2D and 3D contact between any combination of modal flexible bodies and rigid body geometry

"Adams Car was instrumental to tune all subsystems at their best before any real prototype was available… Testing several configurations on the virtual prototype required a matter of hours; doing the same on the real prototype would have been impossible”

Dr. Peter Tutzer, Bugatti

Vertical Solutions:

Adams Car

- Explore the performance of your design and refine your design before building and testing a physical prototype

- Analyze design changes much faster and at a lower cost than physical prototype testing would require

- Vary the kinds of analyses faster and more easily

- Work in a more secure environment without the fear of losing data from instrument failure or losing testing time because of poor weather conditions

- Run analyses and what-if scenarios without the dangers associated with physical testing

- Perform a repeatable set of tests on a global basis, ensuring that you work with common data, tests, and, most important, results

Adams Car Ride

- Model and simulate the ride quality of ground vehicles

- Create Adams Car assemblies of suspensions and full vehicles

- Analyze model to understand their performance and behavior

- Use modeling elements important for ride quality as in Adams Car models

- Analyze the modeling elements independently from other systems using a modeling element test rig

- Use four-post test rig to support a variety of time-domain analyses

Adams Car Truck

- Apply component, suspension and full-vehicle templates specifically for heavy truck and bus

- Model multi-axle, multi-subsystem assemblies that are common in the trucking industry

- Perform component, subsystem, and full-vehicle analyses in one single environment

- Explore multiple what if design scenarios with the template-based parametric modeling approach

- Animate vehicle or subsystem motion onscreen

- Display graphs of key parameters

- Produce standardized test reports

Adams Driveline

- Model and simulate driveline components and study the dynamic behavior of the entire driveline during different operating conditions

- Explore the interaction between driveline and chassis components, such as suspensions, steering system, brakes, and the vehicle body

- Apply a specific torque to your driveline model

- Define a different friction coefficient for different wheels in your model

- Define a slope of your road to study the performance of your driveline model

- Alter the driveline geometry and analyze the driveline again to evaluate the effects of the alterations

Adams SmartDriver

- Bring a vehicle to its dynamic limits or near targets you define

- Improve handling, durability, or ride performance of the vehicle model based on predicted performance Adams SmartDriver computes

- Investigate system-level dynamics of the vehicle model, while requiring minimal setup

- Calculate a limit (maximum performance) speed profile over the reference path

- Check the speed profile using a fast, simplified vehicle model

- Perform an analysis of vehicle states over the trajectory, searching for path locations that cannot be traveled with the current target speed during the full dynamic simulation

- Calculate four additional limits using the parameters specified and theoretical limits of the vehicle

- Creates a speed profile that brings the vehicle to both vehicle limits and user-defined ones

Adams Tire

- Use with Adams Car, Adams Chassis, Adams Solver, or Adams View for adding tires to your mechanical model in order to simulate maneuvers such as braking, steering, acceleration, free-rolling, or skidding

- Model the forces and torques that act on a tire as it moves over roadways or irregular terrain

- Calculate the forces and moments that tires exert on a vehicle as a result of interaction between the tires and the road surface

- Apply handling analyses to study vehicle dynamic responses to steering, braking, and throttle inputs

- Apply ride and comfort analyses to assess the vehicle’s vibrations due to uneven roads with short wavelength obstacles, such as level crossings, grooves, or brick roads

- Apply 3D contact analyses to generate road load histories and stress and fatigue studies that require component force and acceleration calculation

Adams Chassis

- Simulate full vehicle events (such as steady state drift, throttle off in turn, and constant radius)

- Simulate half vehicle events including dynamic load case and static vehicle characteristics

- Use with Adams Insight to perform systematic experiments on vehicle model

- Study the effect of multiple design variations

- Optimize the design

- Address the robustness issue