Multidiscipline Simulation Software Supplier, Linear and Nonlinear Finite Element Analysis (FEA), Control Systems Simulation and more

Explicit Dynamics and Fluid Structure Interaction

Perform explicit Transient Dynamic Solution for Crash, Impact and Fluid-Structure Interaction Studies for improved product safety and reduced warranty costs

Dytran is an explicit finite element analysis (FEA) solution for simulating short-duration events like impact and crash, and to analyze the complex nonlinear behavior that structures undergo during these events. Dytran enables you to study the structural integrity of designs to ensure that final products stand a better chance of meeting customer safety, reliability, and regulatory requirements.

Dytran delivers a structural, material flow and coupled FSI analysis capabilities in a single package. Dytran uses a unique coupling feature that enables integrated analysis of structural components with fluids and highly deformed materials in one continuous simulation.

Accurate, Robust Analysis for your Industry

AIRBAG DEPLOYMENT

Dytran’s accuracy has been proven through correlation with physical experiments. Dytran helps engineers predict how a prototype would respond to a variety of real-world dynamic events and to examine potential causes for product failure. Some industry application examples include:

- Aerospace Applications: Aircraft ditching, fuel tank sloshing and rupture, bird strike simulation, engine blade containment, aircraft crashworthiness, seat design and safety, aircraft and cargo containment hardening

- Automotive Applications: Airbag design and occupant safety (out of position studies), dummy modeling and seat design, vehicle impact and crash testing, tire hydroplaning, fuel tank sloshing and rupture

- Military and Defense Applications: Shaped charge simulation and weapons design, projectile penetration and perforation of targets, hydrodynamic ram (HRAM), ship collision, underwater shock explosion (UNDEX), blast resistance and survivability

- Other Industrial Applications: Bottle and container design, paper feeding, drop testing, sports equipment impact analysis, packaging design

Unique Combination of Simulation Technologies

HYDROPLANING

MORTAR LAUNCH

Dytran’s innovative ability to model the interaction of adaptive, multiple Eulerian domains around coupling surfaces as they move and deform gives you the power to analyze complex FSI scenarios that are often too difficult or impossible to simulate with other software tools, such as:

- Multiple objects impacting multi-layered structures (For example, determining the effect of multiple bird strikes against aircraft structures while in flight)

- Catastrophic structural failure with fluid leakage or penetration (For example, examining a vehicle’s ability to withstand a crash that would result in fuel tank crushing and fuel spillage)

- Fluid filling and sloshing within an enclosed volume (For example, designing baffles to optimize NVH characteristics for fuel tanks)

Dytran for Maximizing Productivity

RAMJET

BLAST UNDER VEHICLE

Through continuous enhancements, Dytran has delivered productivity improving capabilities with each new release. Some of the recent technology enhancements include:

- Distributed Memory Parallel capability of Eulerian solver and coupling surface computation for improved performance gains in FSI applications

- Cyclic flow boundary to help reduce model sizes in simulation of turbines, flow between rotating structures and pipe flow problems

- Body forces that can be applied on different materials inside a particular region defined by a box, sphere, cylinder or a surface

- Graded Mesh for Euler: With graded meshes, one side of an Euler element can connect to the sides of several other Euler elements, i.e. to “glue” a fine mesh to a coarse mesh, providing an effective modeling flexibility, especially the ones that are only locally non-uniform. This capability will benefit important FSI applications such as airbags/sloshing and blast analysis

- Non-Uniform Euler Mesh: Capability to allow non-uniform Euler meshing by defining a biased ratio between smallest and large mesh-sizes, thus providing another way for modeling flexibility. Besides, both Graded Mesh and Non-Uniform Mesh for Euler can be used together. This is useful with UNDEX simulations

- Speed up of Axi-symmetric mesh models through time step determination based on the axial and radial directions

- Naval shipping and UNDEX applications can now use a special boundary treatment defined based on hydrostatic pressure profile

Transient Structural Analysis (Crash/Impact)

FAN BLADE OUT

BOTTLE MANUFACTURING

Dytran uses explicit technology to solve transient dynamic problems. Solid, shell, beam, membrane and connectors and rigid elements can be used to model the structures. A wide range of material models are available to model the nonlinear response and failure. These include linear elasticity, yield criteria, equations of state, failure and spall models, explosive burn models and composite materials to name a few. Contact surfaces allow structural components to interact with each other or with rigid geometric structures. This interaction may include frictionless contact, sliding with frictional effects and separation. Single surface contact can be used to model buckling of structures where material may fold onto itself.

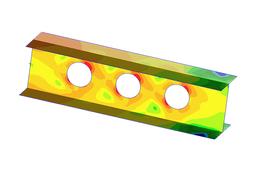

Fluid-structure Interaction

CONTAINER DROP TESTING

SLOSHING

Eulerian solvers are typically used for solving fluid problems, while Lagrangian solvers are used to solve structural problems. However, many real world situations need to account interactions between fluids and solids – deforming solids affecting fluid flow and fluid flow deforming a structure. Problems like fluid sloshing in a tank, airbag inflation, hydroplaning etc. can only solved with fluid-structure interaction accounted for.

Both Lagrangian and Eulerian solvers are available in Dytran to enable modeling of both structures and fluids in a single model and simulate the interaction between them. Interaction between the fluids and structures is achieved through a coupling surface created on structures (Lagrangian domain).

High Performance Computing

Dytran makes use of the latest numerical methods and high performance computer hardware. It provides cost-effective solutions on the latest generation of computers ranging in size from desktop machines to supercomputers. In addition, some applications can exploit the parallel processing facility for distributed memory systems.