Multidiscipline Simulation Software Supplier, Linear and Nonlinear Finite Element Analysis (FEA), Control Systems Simulation and more

FE Based Durability Solution

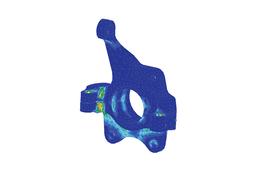

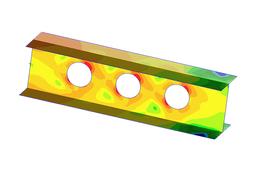

MSC Fatigue is a FE-based durability and damage tolerance solver, and is the only solution that can deal with the full range of fracture and fatigue life calculations for static and dynamic problems in both the time and frequency domain.

Some estimates put annual costs in the United States due to premature fatigue fractures in structural components at as much as 4% of the gross domestic product. Yet testing against repeated loading cycles, sometimes millions of times over, is often too expensive and time consuming to be practical.

Finite element analysis programs can tell you where stress “hot spots” exist, but on their own can't tell you whether those hot spots are critical areas for fatigue failure, or when fatigue might become a problem. To avoid contributing further to this statistic, many manufacturers simply accept long prototype-development cycles, overweight components, unpredictable warranty claims, and loss of customer confidence.

MSC Fatigue enables durability engineers to quickly and accurately predict how long products will last under any combination of time-dependent or frequency-dependent loading conditions. Benefits include reduced prototype testing, fewer product recalls, lower warranty costs, and increased confidence that your product designs will pass required test schedules.

The advanced life estimation capability, MSC Fatigue allows users to perform comprehensive fatigue analysis with the same FE results that are used for stress analysis. The environment seamlessly enables CAE, dynamic analysis and durability to be managed in one user friendly interface. It includes advanced modules developed by MSC Software over a 20 year period as well as more recent modules developed as part of the nCode DesignLife suite of programs.

MSC Fatigue Capabilities

MSC Fatigue is a proven solution for predicting the endurance of your designs and sets itself apart from alternatives by enabling you to:

- Interactively optimize the fatigue life of your designs.

- Effectively work with tightly connected fatigue calculations for dynamic systems within CAE environments.

- Benefit from the numerous features continuously enhanced and introduced in each release of MSC Fatigue.

- Easily monitor, start, stop, and audit your fatigue life analyses at various stages.

- Use sophisticated multi input frequency based dynamic tools.

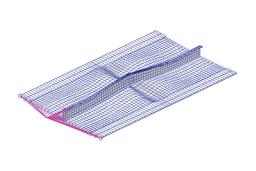

- Predict the longevity of welds with MSC Fatigue's comprehensive weld technologies.

- Use all of the latest fatigue capabilities included in each release of MSC Fatigue and nCode's Design Life.

- Extend the analysis of engine fatigue with a newly implemented "stress gradient" method.

- Simulate fatigue behavior arising from static, dynamic and thermal events.

Related Information

Nastran Embedded Fatigue (NEF)

An entirely new concept for CAE based fatigue calculations.

For the first time the fatigue analysis step is being done as part of the solve process and not as a post processing task. This improves current practices which can be cumbersome and time consuming. NEF revolutionizes the way current calculations are done because there is a dramatic reduction in the number of miscellaneous files that have to be managed (improved durability management) and a corresponding reduction in the overall process time a large job can take.

With Nastran Embedded Fatigue (NEF), Large stress (intermediate) files are no longer be needed. So there is no stress files to transfer as well as reduction in CPU (memory) requirements and the associated ability to process fatigue calculation in memory. In this way full body fatigue calculations are possible for large models.

World Class Training and Engineering Services

MSC Software is able to utilize some of the worlds leading experts for the provision of both fatigue training classes and engineering services. Fatigue training can either be software focused (PAT319) or technology focused (NAS319). MSC Software can even offer a bespoke Durability Management Quick Start Project (NAS399) aimed at users currently employing GUI based fatigue analysis processes who want to switch to a solver embedded approach.