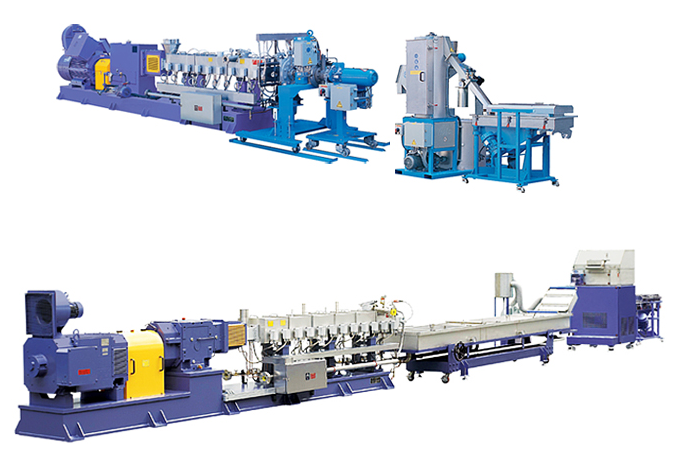

Manufacturer of twin screw extruder for plastic processing

The most commonly used system.

The polymer compounded in the extruder passes through the Breaker plate of the die head at the end of the barrel.

The polymer is discharged through a die nozzle into multiple strands by extrusion.

The polymer through the nozzle is cooled in a water-bath, dried with air wiper, and cut into about 3-6mm length in the pelletizing machine.

The cut pellets are classified into quality products, dust and long-cuts according to their size using a vibrating screen.

The quality products are transferred to storage or packing process.

ㆍPolymer production and pelletizing

ㆍPolymer blending and alloying

ㆍMulti-purpose dispersion and concentration

ㆍPolymer material modification

ㆍFiber reinforcing materials & Fiber-glass, Graphite, Talc, Clay, Carbon black Etc.