The electromagnetic drives generate linear motions and are operated via thyristor controllers.

|

Dosing, packaging, feeding JD dosing drives are ideal for dosing, mixing and feeding applications in the packaging, weighing and automation industries, at low to medium throughput rates. |

Stable operation In order to obtain the optimum vibration parameters, even under varying influences of the conveyed material, every drive unit is tuned in our workshop to the effective weight required by your application. |

|

Continuously adjustable speed The motion amplitude can be continuously adjusted during operation via the controller. The conveying speed can thus be adjusted from standstill up to the maximum performance via potentiometer or target value. |

Ready for immediate operation The drives are also ideal for clock cycle operation be-cause the drive reaches maximum motion amplitude as soon as it is started and it comes to a stop immedi-ately after being switched off. |

Connection

Please note that dosing drives are operated via a Thyristor controller. Details on our controllers in the TK series are given on page 24. Please use only the specified moving-iron instruments for measuring the current.

Centre of gravity

The center of gravity of the trough top fixture must be situated on the X-X line for all types. The dimension „K“ states the intersection with the bearing surface.

| Mains voltages | 115/230 V, 50/60Hz |

| Optional | 42-230 V, 50/60Hz |

| Switch-on time | Operating mode S1, 100% |

| Protection system | IP 65 as per EN 60 529 |

| Paintwork | Hammer tone finish pure silver 91 |

| Optional | SSC 1000, USDA approved |

| Thyristor controller | TK5 |

Maintenance-free

JVM dosing drives generate only little noise, are maintenance-free and are designed for continuous operation. The tried-and-tested engineering and the compact, mini-

mised dead point construction in protection system IP65 ensures operational reliability and easy cleaning.

Adapted model series

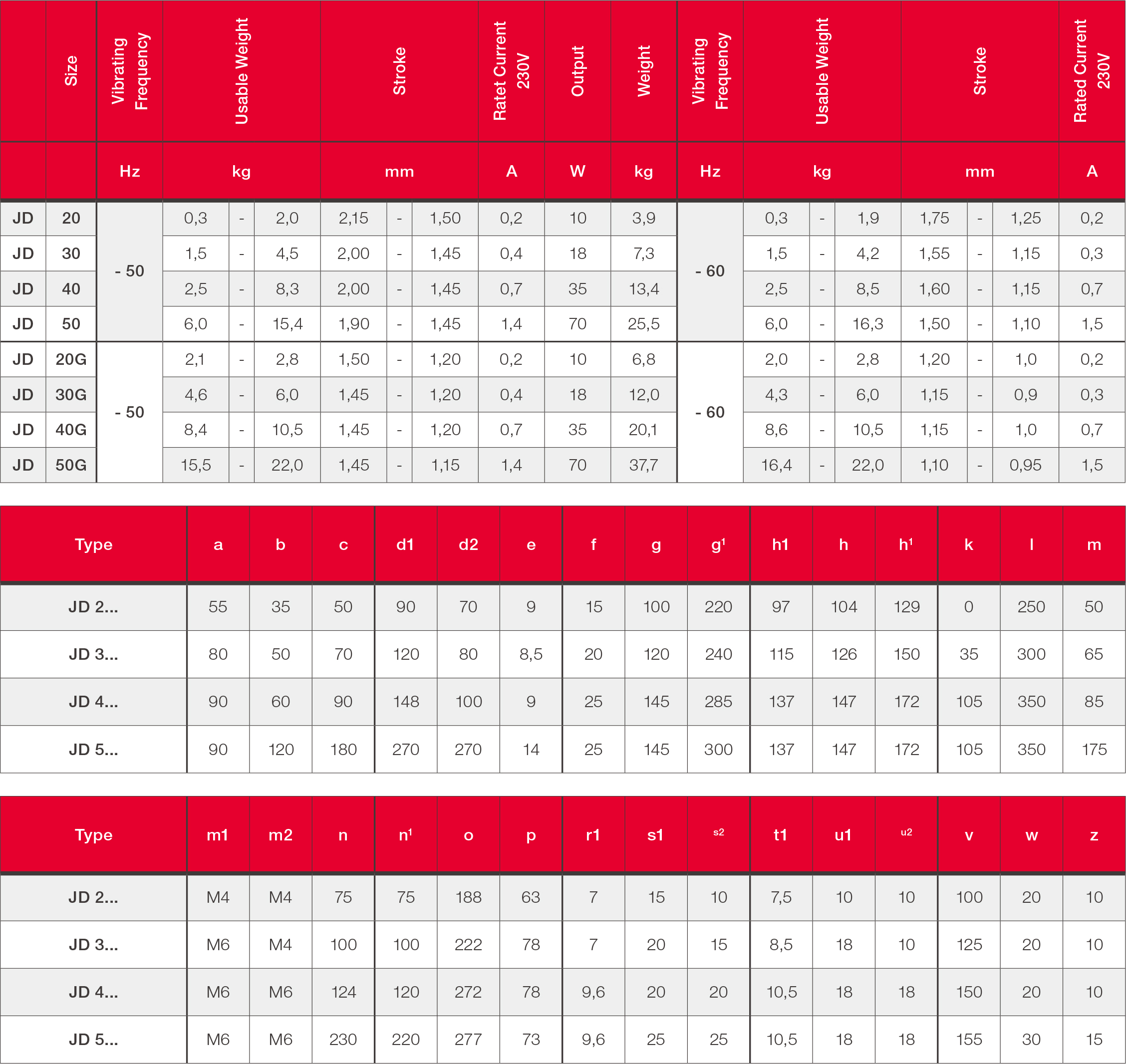

JD drive units are available in four sizes, and also in „G“executions for higher effective weights. We would be happy to advise you on special models, such as for higher oscillation amplitudes.

Mounting

Standard drive mounts are rubber buffers with threaded connection bolts as standard. Other options are available upon request.

Explosion protected models

Dosing drives in explosion protected, ATEX execution (JDA/JDE) may only be operated in conjunction with our protective unit „N“.

Tip

Using several drive units on one machine allows for longer conveying routes, and /or higher design weights.