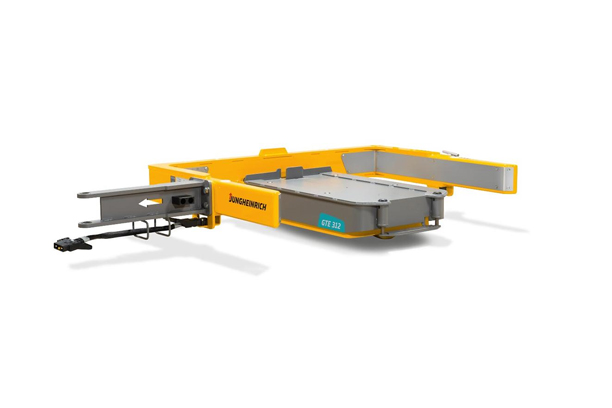

Under Pallet Carrier UPC

Under Pallet Carriers that travel autonomously in the pallet channel form the basis of our shuttle compact warehouse system — a complete solution consisting of the channel racking, carrier truck and carrier.

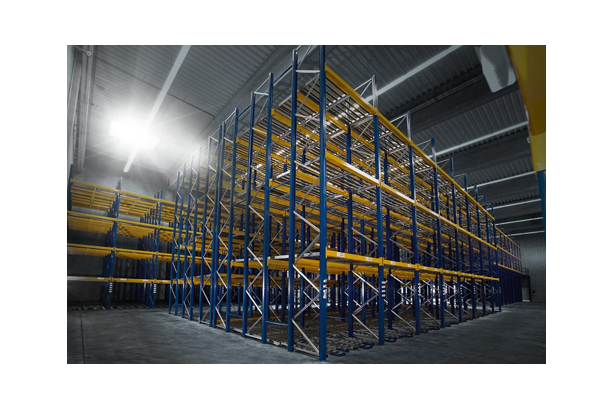

The advantages are clear: The shuttle moves independently of the carrier truck under the stored pallets in the channel. This type of rack operation requires fewer aisles and allows for the compact storage of more pallets across the same warehouse space.

Stacking and retrieval can also be carried out according to the LiFo or FiFo principle. For maximum flexibility, different variants of the shuttle system allow the handling of various load carriers, such as Euro pallets or industrial pallets in the same racking system.

Sensors automatically detect the size and position of the pallets and prevent collisions with other pallets. In order to offer the greatest possible protection to man and machine in automated warehouse operation, our UPC shuttles are optionally equipped with the PPS personal protection system.

✔ Collision-free stacking and retrieval of pallets.

✔ Flexible handling of different pallet types.

✔ Optimal use of space thanks to compact storage.

✔ Virtually any Jungheinrich truck can be used.

✔ Stacking and retrieval according to the LiFo and FiFo principles is possible.

Features

Increased utilization of space

- Compact storage enables more pallets to be stored in the same footprint.

- Optimum volume utilization with a fill level of up to 90%.

- Smallest possible racking compartment heights due to the low overall shuttle height of 145 mm.

Optimum energy efficiency

- Improvement of the energy balance due to the compact construction.

- Optional energy-saving mode.

- Suitable for use in the deep freeze store.

Economical two and three-shift operation

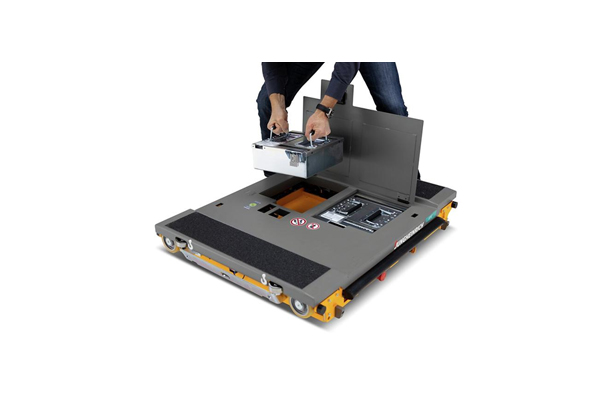

- The guaranteed operating period of 8 to 10 hours with a fully charged battery pack.

- The battery trays enable batteries to be changed in seconds.

- Separate battery charger for easy charging at any 230-V mains socket.

Greater reliability

- Round-the-clock availability of more than 4,700 Jungheinrich service engineers worldwide.

- 98% spare part availability with overnight delivery option.

Conformity with standards

- All Jungheinrich shuttle systems fulfill the applicable standards and directives.

High quality and safety standards

- RAL quality seal: regular inspection of quality and safety according to stringent guidelines by an independent institute.

- Independently conducted inspections at the production facilities to ensure constant quality at all sites worldwide.

Safety equipment for safe working

- Comprehensive safety equipment such as impact protection bars, sensors for obstacle and overhang detection, and an emergency stop guarantee reliable and safe shuttle operation.

- Optional equipment with pallet stops, side gratings, and bumpers for optimum protection of the goods.

- Optional integration of a stationary aisle protection system.

Various load carriers

- Euro pallets.

- Industrial pallets.

- Chemical pallets.

- Euro and industrial pallets in the same racking system: combination shuttle with sensors for detecting the pallet size.

- Other variants are available on request.

Flexible warehouse strategy

- Suitable for FIFO and LIFO principles (also as a retrofit).

Different applications

- Can be operated with a wide range of industrial trucks.

- Can be used problem-free in deep freeze down to -30°C (optional).

Optional functions

- Virtual channel separation for the LIFO operation of both channel sides, each with one shuttle.

- Compression: time-saving storage or removal, e.g. at shift end.

- Multiple removals: automatic removal of a predefined number of pallets or the entire channel.