FDA - Automated Dynamic Handsheet Former

Principle

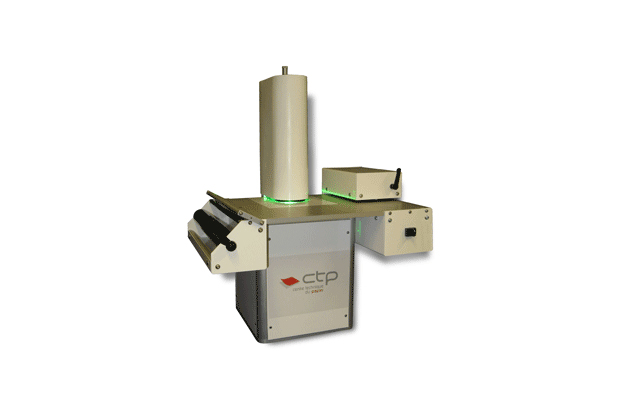

The uniqueness of the FDA resides in its handsheet formation principle which is completely different from classic handsheet formers. In fact, the FDA uses a process very similar to industrial PM sheet production. The sheet is formed by the projection of pulp on a wire positioned on the ID of a rotating cylindrical jar. The wire is completely submerged in a water wall. The pulp projection is accomplished using an injector nozzle fixed on a delivery tube sweeping vertically up and down inside the rotating cylindrical jar. The final basis weight of the sheet depends on the consistency of the pulp, the number of nozzle sweeps and the pulp flow. A scoop system bails out the water wall after the sheet is formed and the water remaining in the sheet is drained by centrifugal force. After the sheet is drained it can be removed along with the wire from the cylindrical jar for pressing and drying.

Advantages

The main advantages include:

- The handsheet shape is rectangular.

- Sheet lookthrough is excellent.

- The fiber orientation is dependent on jet to wire speed ratio (both are adjustable); therefore, it is possible to obtain orientated handsheets.

- The retention of fillers, chemicals or dyes is excellent.

- The distribution of elements in the sheet thickness is similar to a PM produced sheets.

- A large range of fiber types can be used; short or long fibers, synthetic fibers (non hydrophobia), recycled fibers, nonwood fibers, etc.

- A large range of basis weight sheets can be made from fine papers to board.

- It is easy to make bijet or multi jet sheets with excellent adhesion between the various grades.

- Rectangular handsheets can be pressed, dried, calendared, coated or sized, and tested as normal paper.