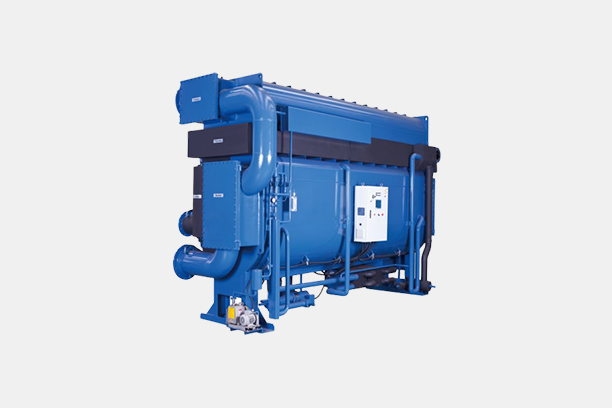

The double-effect, exhaust-gas driven absorption machine consists of an evaporator, absorber, condenser, high- temperature and lowtemperature generators, solution heat exchangers, refrigerant and solution pumps , purge system, controls and accessories. During the cooling mode, the machine operates at the condition that under vacuum,

water boils at a low temperature. Under typical operating conditions, this occurs at approximately 4.4oC (40oF), thereby cooling the chilled water that circulates through the evaporator tubes. A refrigerant pump is used to spray the refrigerant(water) over the evaporator tubes to improve heat transfer.

To make the cooling process continuous, the refrigerant (water) vapor must be removed as it is produced. To accomplish this, a lithium bromide solution (which has a high affinity for water) is used to absorb the water vapor. As this process continues, the lithium bromide becomes diluted, reducing its absorption capacity. A solution pump then transfers

this diluted solution to the generators where it is re-concentrated in two stages (double-effect) to boil off the previously absorbed water. A variable frequency drive on the solution pump automatically maintains optimum solution flow to the generators at all operating conditions for maximum efficiency.

The diluted solution is pumped to the high-temperature generator where it is heated and re-concentrated to a medium

concentration solution by the exhaust heat from the gas turbine or reciprocating engine exhaust gas. The medium concentration solution from the high-temperature generator flows to the low-temperature generator where it is heated and re-concentrated to a strong solution by the high temperature water vapor released from the solution in the hightemperature generator.

Since the low-stage generator acts as the condenser for the high-stage generator, the heat energy first applied in

the high-stage generator is used again in the low-stage generator, thus reducing the heat input by approximately 45% as compared to an absorption chiller with a single-stage of re-concentration. The water vapor released in the shell side of the low-stage generator, in addition to the now condensed water vapor from the tube side of the low-stage

generator, enters the condenser to be cooled and returned to a liquid state. The refrigerant water then returns to the evaporator to begin a new cycle.

To remove heat from the machine, cooling water from a cooling tower is first circulated through the tubes of the absorber to remove the heat of vaporization. The water is then circulated through the tubes of the condenser. The re-concentrated (strong) solution from the low-stage generator flows back to the absorber to begin a new cycle.

For efficiency purposes, the medium concentration solution from the high-stage generator is passed through the high-temperature solution heat exchanger to pre-heat the diluted (weak) solution, while pre-cooling

the medium concentration solution. The re-concentrated (strong) solution from the low-stage generator is passed through the lowtemperature solution heat exchanger to pre-heat/pre-cool the solution before being returned to the absorber.

During the heating mode, the cycle follows a different vapor flow path than that undertaken for cooling and does not use the typical absorption process. In addition, the absorber-condenser cooling water circuit is drained and thus not operated, since all heat rejection from the machine is designed to take place through the evaporator (now the heating

bundle) in a classic two-pipe system that utilizes only the evaporator nozzles.

High temperature water vapor produced in the high-temperature generator section is passed directly to the evaporator via the absorber where it condenses and transfers its heat to the water circulating through the evaporator tubes.

This condensed water then flows to the absorber section where it mixes with the concentrated solution returning from the high-temperature generator. The diluted solution is then pumped back to the hightemperature generator to repeat the vapor generation phase for the heating function. Quick changeover from cooling to heating is accomplished by switching the positions of two hand valves, draining the absorber-condenser water circuit and putting the machine into heating mode by changing the position of a switch in the control panel.

The hot water temperatures is 60oC (140oF) as a standard without additional components and 79oC (175oF) as an option with the additional heat exchanger.