Vacuum hot heater boiler manufacturer, Piping, Vacuum hot, No pressure & Soil sterilize type boiler and more

This control device monitors and controls steam pressure not to abnormally increase nor decrease steam pressure for maintaining stable pressure condition.

Unmanned automatic running to resolve inconvenience of manual operation completely.

Special features

1. Displaying steam pressure, pressure setting, running status by using 7-segment display and LCD Lamp

2. Available to check the status of steam power valve (open, ready) through LCD LCD

3. Setting pressure status in open, ready or close

4. Available to set running time and waiting time for each level in 10 stages.

Front displayer

1. Content selection display - Users can check what is on the displayer.

2. Running status display- Displaying the status of steam power valve(open or ready) and running/stopping.

3. Pressure display- Displaying current pressure, running stage, running time, and mode change.

4. Setting display - Displaying running pressure, running/waiting time by running stages and also displaying set-up value of each stage

5. Control switch - Changing display, checking and set-up values.

Pushing the setting switch for more than 3 seconds shifts from automatic to manual or vice verse.

If manual is selected, controlling will be done with (up) and (down) switch manually and all of the movements regulated by pressure will be stopped.

2way control valve/ON-OFF valve controller

2way control valve, a flange connection type steel valve, is used as a control or interception valve compounded with a controller to secure stable steam supply.

- When installing valves, put the water flow direction and (→) mark on the valve body in the same direction.

- It is better to use a strainer for more safe functions of the valve.

More improved products with a new remarkable filter.

Innovative performance working on lust water or corrosion prevention.

Clean and safe water treatment completely removing causes of corrosion without chemical agent.

Special features

- Perfectly resolving rust stain and corrosion matters.

- Life extension of building pipes.

- Effective on buildings of 10 years or more, removing dissolved oxygen.

- Ultra filtration filter.

- Displaying running status.

- New safe filter module

- Running time designation and control.

- Water saving running.

- Compact and light.

- Antifreezing.

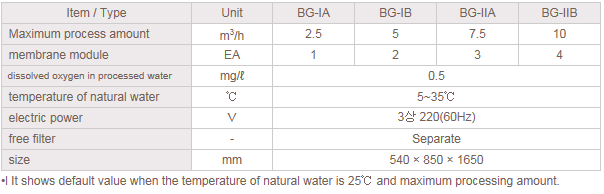

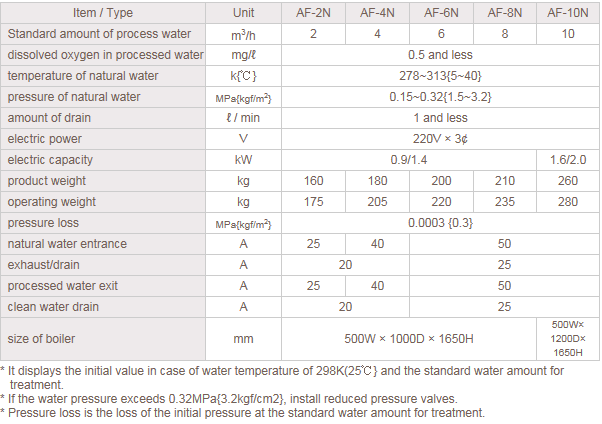

Deaerating membrane device

Principle of deaerating

Water passes through one side of oxygen permeable membrane while dissolved oxygen in the water is removed at the other side of it.

As a result, density of the dissolved oxygen in the water is significantly lowered.

This device only removes oxygen, a cause of corrosion, allowing chlorine to remain in the water.

Therefore, it is an ideal solution for food factories preserving the safety as drinking water.

Special features for boilers

- Compact and high performance

- Adapting a new type filter with high durability

- Simple operation and fast response

- Economic water saving type

New type membrane module with parts authorized by FDA(Food and Drug Administration of USA).

Membrane degassing system (for boiler) is loaded by new membrane module which is adopted in the manufacturing process requiring more clean water.

It eliminates dissolved oxygen in water cleanly and safely without using chemicals.

Simple automatic operation and compact design creates new standard of membrane degassing system for boiler.