Dryer manufacturer, Spray dryer, 4 Fluid nozzle, Cake dryer and more

Product Details

Basic principle

The FLASH GRINDING DRYER can process drying, disintegrating and classification of the materials such as filter cake, paste, etc.

consecutively at one time. It is innovative drying equipment.

* It is not necessary to control the concentration of the raw materials

* As the residence time in the drying chamber is short, from 1-3 seconds, it is useful even for products that are sensitive to

temperature.

* It is essential for the automation of organic and inorganic chemicals. Compared to the existing drying equipment, it has high

thermal efficiency as the size of drying tower is small, which requires a smaller installation space and reduces operation and

maintenance expenses. For such reasons, you can maximize the effect and competitiveness of the products.

Basic procedures

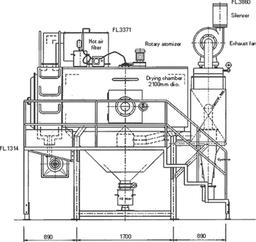

The basic procedures for flash grinding dryer consist of

* Feeding System

* Furnace

* Material collector

The feeding system uses a screw feeder, pump, etc according to the status of the materials and applies an auto supply control

to supply a regular amount. The furnace can be selected for use according to the kinds of fuel and use conditions. It consists of

air inlet, a rotor, a classifier, an outlet, a door, etc., and is designed for convenient cleaning as well as optimal function. As for

the material collector, cyclone, or bag filter, etc., can be used separately or combined, according to demand.

The basic principle of drying, disintegrating and classification

The basic principle of drying, disintegrating and classification

The materials put through the feeding system are disintegrated mechanically by the hot blast and rotor in the drying chamber.

The hot blast enters through the hot blast pipe whirling at high speed due to the influx hole inside the pipe. Then it dries and

transfers the disintegrated materials, moving to the upper duct.

The large sized granules are separated by the classifier and travel down again to the drying chamber at high speed and the

process is repeated for disintegration, drying and moving upwards.

The suitable sized granules are transferred to the material collector through the duct.