Air dryer, Pressure vessel, Storage tank, Energy saving device and more

ㆍFeatures

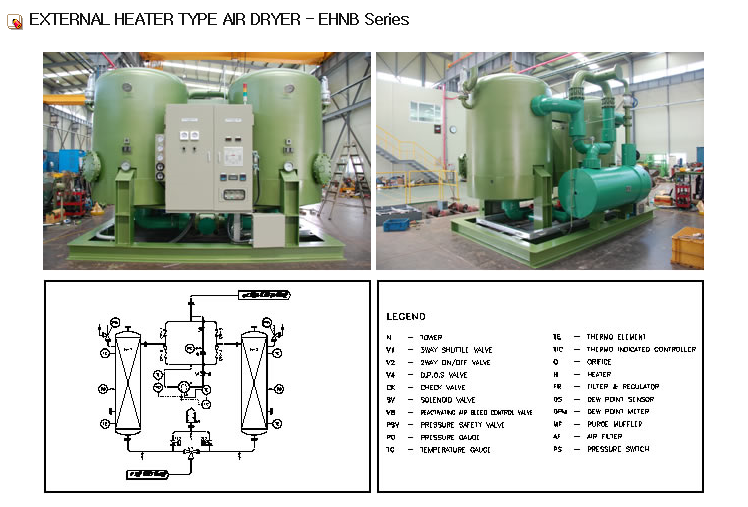

The air dryer is the most common type of heater. To get a heat source during the regeneration of the drying agent, either an electric heater or an external steam heater can supply the heated compressed air to the regeneration tower through ducts in order to heat dehumidifying agents and to cool down the agent with cold dry air. Operators mostly prefer the heater type as the most accepted system. After wet air is supplied to the tower, the absorption tower and strainer are designed to maintain the same quantity and even speed when using a dehumidifying agent and producing dry air at the highest dew point. (Regenerated air consumption: 8~10%).

ㆍProduction specification

Capacity: 20,000 N㎥/HR or more

Dew point: PDP -40℃ to -110℃ or below

ㆍAdvantages and disadvantages

Advantages: Operation and repair are easy and convenient due to its mechanical structure.

Disadvantages: The heater requires a large installation space because it is external in type.