All parts related to quality are precision machined to keep a 0.02 allowance.

- About 40% of part are precision machined. (Single reduction - Adapter type)

- There is no exception for this rule, including even the smallest parts, such as pins and bushings.

We use the right materials.

- We use high-carbon chromium alloy steel (SUJ2 bearing steel) for core reduction parts.

- Materials for core parts are heat-treated to acquire the right material properties.

- High quality bearings are used for input parts directly connected to the high-speed motor

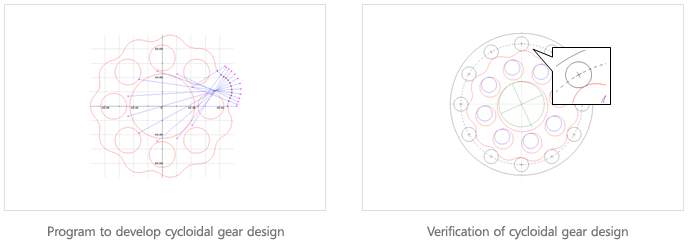

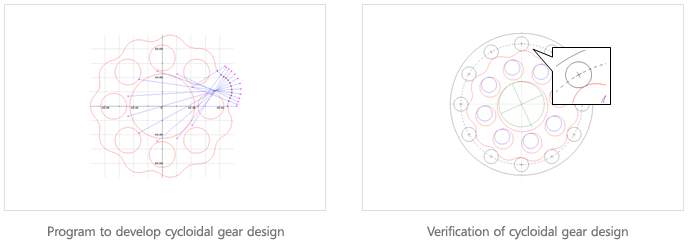

We continuously invest in core technologies to improve our quality level.

- We internalized cycloidal gear design technology the keep upgrading the design.

- We research various technologies te reduce noise/vibration and to increase effciency.

We do NOT compromise on quality standards to reduce cost.

- We do NOT use refurbished or used parts for which we cannot guarantee quality.

- We do NOT accept any expedient design changes the undermine quality standards.

With a high efficient mass production line designed only for cycloidal gear reducers, We have achieved both short lead times and low production costs.

- We have about 45 machine facilities, including automated production facilities.

- We have 22 remodeled machines only the cyloidal gear reducer manufacturing.

- Most of our field workers have more than five years of experience at HDM

The entire production process is effectively managed with an innovative production management system.

- From order to delivery, 2,100 manufactured parts are tracked and managed with one integrated system

- Thus we can maximize production efficiency, resulting in short lead time and low production cost