Broach machine manufacturer, Air leak test machine, Factory automation, Specialized machine design and more

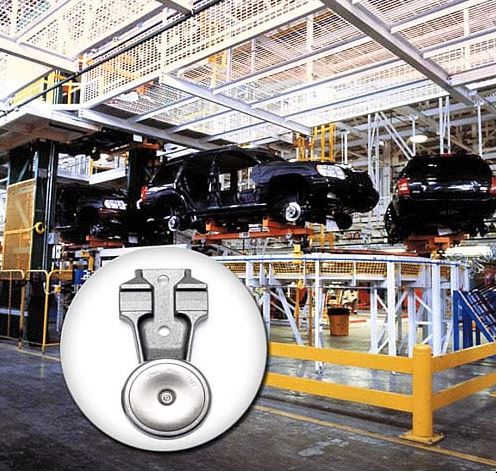

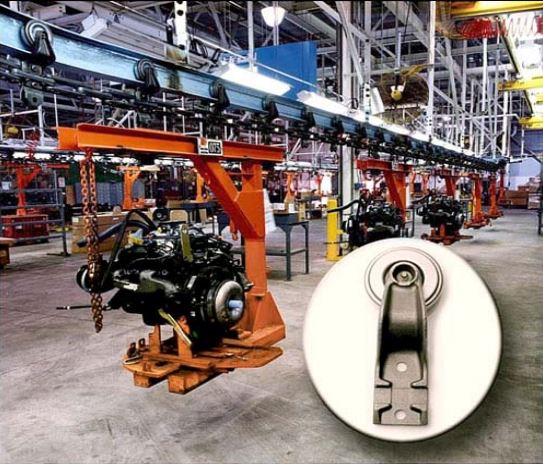

▶ Trolley Conveyor System

Overview

TR-type power & free trolley conveyor is an overhead conveyor system that exhibits diverse functions such as elevation and falling of object, classification, storage and merging.

Our company is equipped with wide variety of models for efficient use on the entire factory space in construction of automated systems for different processes including manufacture, painting, assembly, storage and shipment, and we will provide benefits of productivity to your company based on our unique technologies and experiences.

Features

→ Chain rail and carrier rail are distinguished to freely move products to other conveyor lines for easy layout configuration.

→ Trolley conveyor of our company employes a wide-ranged product transport line with standard trolley chain appropriate for permitted tension, load and use, and it especially has excellent durability.

→ Space is used as return route and storage. Different models are stored and classified into each model for easy return and storage between layers.

→ Products are returned at the right place and timing based on high speed, high frequency, automation and silence to greatly increase productivity.

→ Inspection and maintenance are extremely easy.

Type

→ TR-348

→ TR-458

→ TR-678

→ NZ-75

→ KZ Type

→ KH Type

Use

→ Production line for electrics, electronics and machineries

→ Car body, painting and assembly lines for automobiles

→ Buffer and storage lines between processes

→ Line that supplies and withdraws parts to multiple lines

→ Line to classify and store half-finished and finished products

→ Automation line for entry and exit of goods

→ Pottery production line

→ Assembly, painting and inspection works on the line

→ Automation line for entry and exit of goods

Example of application