Printing Press Manufacturer, Printing, Converting, FLEXOGRAPHIC Solutions, ROTOGRAVURE Solutions and more

Our flexographic units are designed for printing and coating applications.

We offer either vertical or horizontal web path configurations, with air or UV dryers.

Using flexo units on an offset line or on a rotogravure line as auxiliary units is a relevant choice for coating applications or reverse printing (for instance couponing). This hybrid configuration grants a great versatility, all the more since the make-ready of the flexo units is made very easily thanks to the sleeve-type cylinders.

Main Applications

General Folding, Liquid Packaging, Beverage Carriers, Coating, Reverse Printing

Komori-Chambon expertise

|

Hybrid configurations The Komori-Chambon know-how is obvious in its ability to integrate various printing processes in one production line. Take the best profit out of each solution. |

|

Flexibility The flexo units are configured according to the ink types and related drying devices. The whole production flow is 100% under control. |

|

Agility Independent servomotor-driven shafts allow precise and safe operations. |

|

Safety The system is protected from wrap-arounds by sensors, web break detector, torque control and reversible clutch parts. |

Production flow insights

|

▼ |

- The design to print is split by color and transfered onto flexible printing plates - The initial printing costs in flexo are low when conventional plates are used (rubber) - HD flexo plates (photopolymers) come at a higher price but deliver a higher printing quality. |

|

|

▼ |

- Automatic circumferential and lateral registration - Automatic on/off from main desk of anilox roll and impression cylinder - Heater temperature controlled with pre-setting (air temperature). |

|

|

▼ |

- The inking system includes: Chambered Doctor Blade System, Coating circulation and automated cleaning, Automatic internal functions - The driving and pressure adjustment of the printing cylinder and of the anilox cylinder are motorized as well as the side register setting - Ink circulation is controlled thanks to a viscosity and level regulation. |

|

|

▼ |

- Depending on the ink type, water-based or solvent-based, the flexo unit in configured either for air drying or for UV or EB drying. - The web path is either vertical or horizontal. |

|

|

▼ |

- Coating and reverse printing can be performed with the flexo units - Offset and rotogravure units can be combined depending on the job constraints |

|

CHANGEOVER |

- Job changes are easy to operate thanks to the ink washing sequence, the lightweight sleeve design and the semi-auto bearing parking sequence |

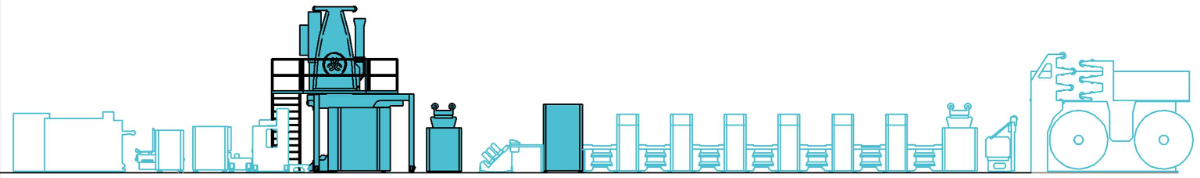

Available configurations

|

ROLL TO ROLL by-pass The press includes a rewinder right after the printing units For more flexibility, the line can include a rotary die-cutter and a by-pass to transfer the web to the rewinder

|

|

ROLL TO ROLL direct The press includes a rewinder right after the printing units |

|

ROLL TO BLANKS The best configuration to take the maximum profit of your production line. The inline rotary die-cutter, placed right after the printing stage, can be followed by a high speed delivery solution. The carton roll is transformed into ready-to-ship blanks within 10 seconds.

|

|

ROLL TO SHEETS The printed web can be converted in sheets thanks to a sheeter. The sheets can be converted offline with a flat bed die cutter. |