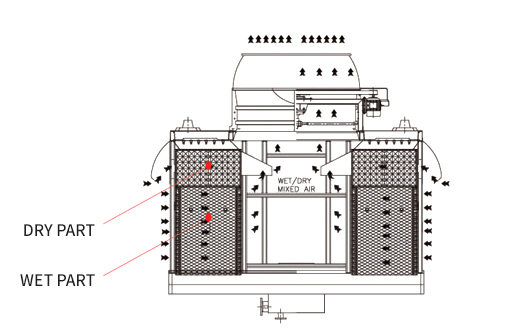

nPKL-TOWER Structure chart

Features of nPKL-TOWER

1. Kimco’s Plume Abatement Technology without coil

The intake air passes through wet and dry sections and mixed together inside of the tower. The plume is reduced because fill-passed air is mixed with high temperature dry air passed through plastic air heater

2. Active control operation through damper

The two-stage damper installed in nPKL, can perform with wet operation/ dry operation/ wet and dry operation, and active control operation. In the hot weather, it is operated so that the cooling efficiency of 100% or more is exerted by the wet-only operation. In the cold weather, it is possible to prevent the plume completely by the exclusive operation. Through adjusting the blade opening angle of the independent damper of dry/wet part, The cooling tower can adjust cooling efficiency and reduce amount of plume.

3. Economical plume reduction type cooling tower

The nPKL cooling tower with PVC air heater is relatively inexpensive compared to the conventional smelting tower with stainless steel tube and aluminum fin heating coil. nPKL tower maintains plume reduction, and is equipped with the new test technology and with high efficiency and with low price.

4. Anti-corrosion light weight and plume reduction cooling tower

PVC air keeps the best conditions in place for the life from the fatal disadvantage of metal air bubbles, corrosion. In addition, the operating weight is reduced by more than 30% compared to the plume reduction type cooling tower equipped with a metal large fin tube coil. And it t reduces the load of the building due to the characteristics of the cooling tower installed on the roof. By reducing the load on the entire building, it can serve as a solution for reducing construction costs and extending building life.

PKL Line Structure chart

Why does plume come out from the cooling towers?

1. The cooling tower system includes a function of reducing the temperature of the water through ventilating the air forcibly and bringing in contact with the cooling water. The intake air of the cooling tower system comes into contact with the warmed cooling water, and heat exchange through the reducer. As the temperature of the air rises, the maximum limit of the water vapor increases, then a part of the cooling water evaporates into water vapor and mixes with air heat exchange effect of the latent heat.

2. When the high-temperature saturated moisture vent is discharged from the cooling tower system to the atmosphere, the discharge air is cooled to near ambient temperature while being mixed with the atmosphere. Since the maximum value of the saturated vapor of the discharged air is lowered again, the water vapor is not in a gaseous state and is condensed with water. This condensed water is visible in the form of a small droplet is called the plume effect.

How to reduce plumes

The most common method for the plume abatement is to discharge the cooling tower outlet air in the form of less saturated moisture air rather than saturated one. Most of the cooling tower outlet air has a relative humidity close to 100%, but the method makes the air have a margin of 10% to 30% before it is totally saturated, which can further contain water vapor.