Injection Machine Manufacturer

The WIZ-E Series is the result of years of research and experience in the development and manufacture of injection molding machines. These exceptional machines combine the benefits of servo electric technology, an injection speed/pressure control algorithm, conformance to safety standards, a 5-point toggle clamping system designed by FEA analysis, and a high speed injection molding mechanism.

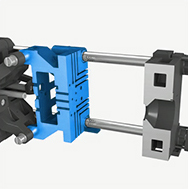

Center press typed moving platen for precision molding

Extended daylight (80 ~ 400 Ton)

3% ~ 20% up compare to previous model

Extend tie bar distance (80~ 400 Ton)

Horizontal 7% ~ 17% UP x Vertical 2% ~ 15% UP compare to previous model

KEBA CONTROLLER

Real time data setting and operation

User-friendly UI

Hot Runner Controller(option)

USB port, Key switch (Option)

Manual operation button

Speed /pressure precedence mode

User can select the mode depending on products

Pressure precedence mode (applying for heavy wall products or good looking products)

Speed precedence mode (Applying for thin products )

Increased injection volume

13~27% up compare to previous model

Applying strong & quick response AC servo motor to realize high injection speed

Injection Speed Maximum 300mm/s

Servo motor controls individually and simultaneously

Platen open during plasticizing / Ejection durong opening planten /Injection during increasing pressure

Reduce cycle time (productivity improvement)

Business Lines

|

Home appliances LS Mtron’s injection&molding machine is specialized for heat resistant polymer resin which is used on 24hours working device - mobile phone, electric watches, computer etd.,- Thus, you can achieve mass production quality.

|

|

Automotive LS Mtron secure your quality with all automotive industry. with our turnkey solutions, we are your competent partner in all areas of the automotive industry ? from the development stage to reliable and precise high-volume production. |

|

Packaging Packaging industry request more fast and precise machine for high productivity. With our high efficient injection speed and powerful clamping force, our machine enable to produce thin product and reduce the cooling time.

|

|

Medical We offer utmost safety and clean work environment without oil leakage. It is best solution for medical product manufacturing system.

|