Shipyard tools manufacturer, lifting magnet, clamp, magnetic tools for shipbuilding

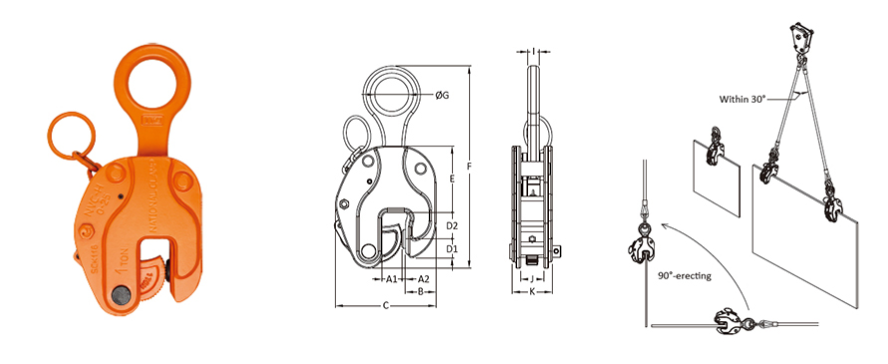

NVC-H

| WLL(TON) | Jaw Opening | A1 | A2 | B | C | D1 | D2 | E | F | ØG | I | J | K | Weight(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 0-20 | 22 | 4 | 28 | 102 | 22 | 32 | 88 | 265 | 45 | 10 | 28 | 56 | 3.3 |

| 0-50 | 52 | 4 | 32 | 166 | 27 | 50 | 120 | 378 | 50 | 14 | 30 | 54 | 6.4 | |

| 1 | 0-25 | 30 | 4 | 38 | 148 | 24 | 40 | 100 | 310 | 55 | 16 | 36 | 60 | 6.1 |

| 0-30 | 35 | 5 | 46 | 162 | 30 | 46 | 108 | 315 | 55 | 16 | 36 | 60 | 6.6 | |

| 0-45 | 50 | 5 | 45 | 190 | 35 | 43 | 118 | 342 | 55 | 16 | 36 | 60 | 7.8 | |

| 2 | 0-30 | 35 | 5 | 54 | 172 | 32 | 46 | 114 | 345 | 58 | 18 | 40 | 68 | 8.8 |

| 10-70 | 75 | 5 | 62 | 256 | 35 | 70 | 160 | 456 | 60 | 19 | 40 | 68 | 17.4 | |

| 30-70 | 75 | 5 | 62 | 247 | 42 | 64 | 155 | 444 | 58 | 18 | 40 | 68 | 15.6 | |

| 3 | 0-35 | 40 | 5 | 58 | 192 | 40 | 48 | 130 | 380 | 60 | 19 | 43 | 71 | 11.6 |

| 30-50 | 55 | 5 | 58 | 208 | 40 | 60 | 130 | 385 | 60 | 19 | 43 | 71 | 13.5 | |

| 30-70 | 75 | 5 | 70 | 260 | 48 | 67 | 155 | 425 | 60 | 19 | 45 | 75 | 18.9 | |

| 40-80 | 85 | 5 | 70 | 270 | 47 | 63 | 155 | 435 | 60 | 19 | 45 | 75 | 19.2 | |

| 5 | 0-45 | 50 | 5 | 65 | 234 | 52 | 50 | 144 | 432 | 60 | 22 | 48 | 84 | 18.5 |

| 0-50 | 55 | 5 | 65 | 240 | 55 | 62 | 148 | 440 | 60 | 22 | 48 | 84 | 20.0 | |

| 30-65 | 70 | 5 | 70 | 252 | 55 | 62 | 148 | 440 | 60 | 22 | 48 | 84 | 22.1 | |

| 30-70 | 75 | 5 | 82 | 265 | 55 | 82 | 177 | 485 | 60 | 22 | 50 | 88 | 26.2 | |

| 40-80 | 85 | 5 | 88 | 288 | 55 | 82 | 180 | 487 | 60 | 22 | 50 | 88 | 27.8 | |

| 8 | 0-50 | 55 | 5 | 85 | 263 | 55 | 64 | 182 | 485 | 65 | 30 | 60 | 104 | 33.5 |

| No. | ASS’Y NAME | No. | PART NAME | No. | ASS’Y NAME | No. | PART NAME |

|---|---|---|---|---|---|---|---|

| 1 | BODY | - | - | 6 | JAW ASS’Y | 6-1 | SWIVEL JAW |

| 2 | SHACKLE | - | - | 6-2 | BOLT & NUT | ||

| 3 | SHACKLE PIN | - | - | 7 | LATCH ASS’ | 7-1 | SAFETY LATCH |

| 4 | CAM ASS’ | 4-1 | CAM | 7-2 | HANDLE RING | ||

| 4-2 | LINK | 7-3 | SPRING PIN | ||||

| 4-3 | SPRING PIN | 7-4 | BOLT & NUT | ||||

| 4-4 | RIVET PIN | 8 | LOCK SPRING | - | - | ||

| 5 | CAM PIN ASS’ | 5-1 | CAM PIN | ||||

| 5-2 | SPRING PIN |

Features

The NVC-H has the built-in safety latch that prevents a work piece from slipping due to the initial clamping force caused by the spring even if the wire rope becomes loose during the operation.

How to use

- Insert a steel plate into the inside end of the clamp's jaw opening and then lock the safety latch.

- Clamp the center of gravity of the work piece in order to equally distribute the weight of the work piece.

Warnings

- Do not exceed the rated capacity specified on the clamp.

- Use a work piece only which falls within the jaw opening range specified in the instruction manual.

- Never lift two or more work pieces with one clamp.

- Lift a work piece only after checking the biting location and the biting condition of the work piece, and the proper functioning of

the safety latch.

-When lifting a work piece, a signal man must be outside the rotation radius of a work piece to send a signal to a crane operator.