Multidiscipline Simulation Software Supplier, Linear and Nonlinear Finite Element Analysis (FEA), Control Systems Simulation and more

Model the realistic behavior of materials and interaction between components

All physical processes are inherently nonlinear to a certain extent. For example, when you stretch a rubber band, it gets harder to pull as the deflection increases; or when you flex a paper clip, permanent deformation is achieved. Several common every day applications like these exhibit either large deformations and/or inelastic material behavior. Failure to account for nonlinear behavior can lead to product failures, safety issues, and unnecessary cost to product manufacturers.

Nonlinear response could be caused by any of several characteristics of a system, like large deformations and strains, material behavior or the effect of contact or other boundary condition nonlinearities. In reality many structures exhibit combinations of these various nonlinearities. MSC Software provides solutions to help you simulate accurately and efficiently systems with any or all of the nonlinearities, with applications encompassing multiple industries.

MSC Software is used for many types of nonlinear simulations:

- Large displacement and large strain analysis

- Post-buckling analysis

- Plasticity and viscoplasticity

- Creep and stress relaxation

- Nonlinear elasticity

- Shape memory alloys

- Powder metallurgy

- Hyperelasticity

- Thermal variation of material properties

- Electrical-thermal-structural coupling

- Manufacturing processes like forming, extrusion, welding, curing and more

- Bolt modeling

- Material damage

- Fracture and crack propagation

- Material wear

- Pyrolysis and abrasion

- Multiphysics

- General large displacement 3D contact

- Friction analysis

- Automatic remeshing

Industry Uses:

- Aerospace and Defense: Landing gear, Wing structures, Fuselage, Seals and hoses, Sheet metal forming

- Automotive: Powertrain, Tire, Seals and gaskets, Exhaust systems, Brakes, Suspension, Gear contact, welding, joints and connectors

- Electronics: Soldering, Welding, Drop tests, Sealing, Switches and connectors

- Energy: Wind turbine blades, Composite blade failure, Gear trains, Packers, blow out preventers, Seals and gaskets, Pipes and casings, Weldments, Drill bits

- Heavy Equipment and Machinery: Gears, Steering yokes, Belts, Hoses, Metal forming, Hose crimping, Wire crimping, Curing, Welding, Extrusion

- Medical: Stents, Catheters, Pacemakers, Dental and knee implants, Prosthetics, Muscle and tissue, Hospital equipment like beds, wheel chairs

- Rail: Tip-over stability study, Structural components, Welding, Joints and connectors

- Shipbuilding: Structural analysis, Riveting, Bolts, Welding, Sealing

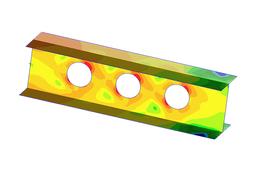

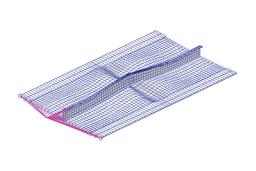

Geometric Nonlinearity

TWISTING OF A BEAM

BENDING OF A PLATE STIFFENED WITH BEAMS

Structures whose stiffness is dependent on the displacement which they may undergo are termed geometrically nonlinear. Geometric nonlinearity accounts for phenomena such as the stiffening of a loaded clamped plate, and buckling or 'snap-through' behavior in slender structures or components. Without taking these geometric effects into account, a computer simulation may fail to predict the real structural behavior.

Material Nonlinearity

SHEET DRAWING

ORTHODONTIC ARCHWIRE MADE OF NITINOL SHAPE MEMORY ALLOY

Material Nonlinearity refers to the ability for a material to exhibit a nonlinear stress-strain (constitutive) response. Elasto-plastic, hyperelastic, crushing, and cracking are good examples, but this can also include temperature and time-dependent effects such as visco-elasticity or visco-plasticity (creep). Material nonlinearity is often, but not always, characterized by a gradual weakening of the structural response as an increasing force is applied, due to some form of internal decomposition.

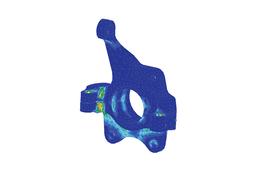

Boundary Condition Nonlinearity

FRICTION CLUTCH

CYLINDER HEAD JOINT AND GASKET

When considering either highly flexible components, or structural assemblies comprising multiple components, progressive displacement gives rise to the possibility of either self or component-to-component contact. This characterizes to a specific class of geometrically nonlinear effects known collectively as boundary condition or ‘contact’ nonlinearity. In boundary condition nonlinearity the stiffness of the structure or assembly may change considerably when two or more parts either contact or separate from initial contact. Examples include bolted connections, toothed gears, and different forms of sealing or closing mechanisms.

Related Products:

- Digimat The Nonlinear Multi-scale Material and Structure Modeling Platform

- Dytran Explicit Dynamics and Fluid Structure Interaction

- FEA, AFEA and TFEA Structural, Nonlinear, and Thermal Simulation Packages

- Marc Advanced Nonlinear Simulation Solution

- MSC Nastran Multidisciplinary Structural Analysis

- MSC Nastran Desktop Multidiscipline Simulation for your Desktop

- Patran Complete FEA Modeling Solution

- SimDesigner CAD-Embedded Multidiscipline Simulation

- SimXpert Fully Integrated Multidiscipline Simulation Solution