Multidiscipline Simulation Software Supplier, Linear and Nonlinear Finite Element Analysis (FEA), Control Systems Simulation and more

Thermal Design Tool for Electronics

HeatDesigner uses core technology from scSTREAM to perform thermal fluid analysis specifically designed for electronic cooling. HeatDesigner's performance is optimized for applications that do not require precise reproduction of fine geometrical curvature to predict an accurate flow field. However, HeatDesigner is capable of accommodating meshes with over one hundred million elements, enabling it to capture fine geometrical details. Like scSTREAM, the major advantages of HeatDesigner are fast calculation times and low memory consumption.

Software Features

Large-scale calculation

Large-scale calculation

In structured mesh, even a complicated model does not need to be modified almost at all and the shape or the scale of a model does not affect the difficulty of mesh generation. In addition, Solver performs a calculation at a high speed in parallel computing and achieves effective processing as the speed increases depending on the number of subdomains.

Multiblock

Multiblock

Mesh can be refined partially to represent a model shape more accurately and perform a calculation more efficiently.

Part library

Part library

The shapes and conditions of frequently used parts can be registered. Conditions include the allocation position, material, and heat generation.

HeatPathView

HeatPathView

The information on temperature of each part and a comprehensive amount of heat release obtained in post-processing of a general CFD analysis is not enough to know the heat path. HeatPathView displays heat paths and the amount of heat transfer in the whole computational domain in a diagram, a graph, and a table, allowing you to find the bottleneck of the heat paths easily.

ElectronicPartsMaker

ElectronicPartsMaker

The tool can create detailed models of semiconductor packages including QFP, SOP, and BGA by specifying parameters, and simplified models using thermal resistor models such as DELPHI models and two-resistor models. Manufacturers of semiconductor packages can provide the data of semiconductor packages as thermal resistor models without releasing the inside information.

Reading wiring patterns

Reading wiring patterns

To calculate heat transfer conditions depending on wiring patterns of a printed circuit board (PCB) in detail, the module can read Gerber data output from an electric CAD tool and import the data as a model for a thermo-fluid analysis. By using Gerber data, a more realistic calculation result can be obtained with the consideration of heat transfer affected by an uneven wiring pattern.

Radiation

Radiation

Radiation heat transfer with the consideration of diffusion, reflection, transmission, refraction, and absorption can be calculated. VF (view factor) method and FLUX method can be used. The lamp function can simulate radiant heat by a filament without detailed shape information of a lamp. In addition to the filament, laser beam and defective radiation specified by half-value angle can be used as a heat source model.

Using structure function from measurement

Using structure function from measurement

Modeling of electronic device is possible by converting result data of heat change over time used for transient heat resistance measurement* into structure function (thermal resistance - heat capacity characteristics). Accurate thermal model can be generated by comparing test and analysis data on the basis of structure function.

Electronic part model

Electronic part model

A wide range of models are available that enable to easily achieve thermal design of printed circuit boards and electronical enclosures, which includes DELPHI (multi-resistor) model, Peltier device and heat pipes. It is possible to consider pressure loss characteristics using slits, and P-Q characteristics of fans using swirling component. Generated models can be added in library.

Panel (heat conduction / transfer / thermal transport)

Panel (heat conduction / transfer / thermal transport)

Material properties and motion conditions can be applied to a panel having no thickness in model, which allows for heat conduction to other parts and heat dissipation to air. This enables the simulations of paper feeding and film drying processes, where thin objects move and go under heating repetitively.

Utility Tools

scMonitor

scMonitor

You can visualize the progress of the simulations in scMonitor during the Solver calculations. You can check, for example, pressure contour of a registered surface and temperature contour and flow vector on axial planes.

LFileView

LFileView

LFileView is a dedicated viewer for L files, which are output during the simulations automatically. You can check the progress of the simulations numerically with variable values for each cycle and the maximum/minimum/average values for the specified output.

VB Interface

VB Interface

The software supports COM technology provided by Microsoft. You can control the software by using Microsoft Office products and Visual Basic (VB). A tool to create and execute the automatic operation flow, scWorkS ketch, is bundled with the software. By using the tool, you can create your original automatic operation flow easily. In addition, you can register the created flow as a template and reuse it.

- Useful functions

- Tool to create a report automatically

- Unique GUI

- Tool to create a model from the 2D data automatically

Parametric Study Tool

Parametric Study Tool

Using the parametric study tool, you can set analysis conditions to multiple cases all at once - for instance, when you run several calculations with modified parameters such as flow rate or amount of heat. The interface is user-friendly with spreadsheet-like settings. You can check, in the same interface, the status of each case and the output parameters such as the maximum/minimum temperature or aveage pressure on a specified plane.

HeatPathView

HeatPathView

Using HeatPathView, you can review heat dissipation measures with focus on each component. The tool enables the intuitive and comprehensive evaluation of heat balance and search of heat dissipation paths. By understanding the flow of heat, you can make your heat dissipation designs more reliable.

scCONVERTER

scCONVERTER

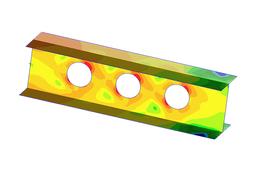

Data (FLD/FPH files) such as pressure, temperature, and heat transfer coefficient obtained in thermo-fluid analyses can be mapped to input data of structural analysis software (Abaqus, I-DEAS, Nastran). In addition, input data of structural analyses can be converted to an FLD or FPH file. scCONVERTER can create an animation file from multiple still images (BMP/PNG files), edit FLD/FPH files, and convert a P file to an FLD file or an FLD file to an iFLD file.

CradleViewer

CradleViewer

The simulation result visualized in Postprocessor can be saved in a file and the file can be opened in a simple viewer. In the viewer, the viewpoint ant the distance can be changed with the mouse and by touch operation*. CradleViewer is provided free of charge. You can share the simulation result even in an environment without Postprocessor installed.

Optimus for Cradle

Optimus® for Cradle

Optimus has a direct interface with scSTREAM, scFLOW and SC/Tetra, and the optimization can be performed without any additional customization. It also supports a creation of an original GUI using API and an optimization using Quality Engineering (Taguchi Method).