Extrusion molding machine, Extruder, Pipe, Air bubble seat machine, Forming machine, Film machine and more

ShinKwang Engineering Co.,Ltd is specialized in the plastic machinery field with many years experience. We can provide a complete production line of Single, Double, Twin screw extruder for compound and recycling Generation for master batch, HDPE, LDPE, PP, EVA+ calcium carbonate, EVA elastomer, Scrap recycling.

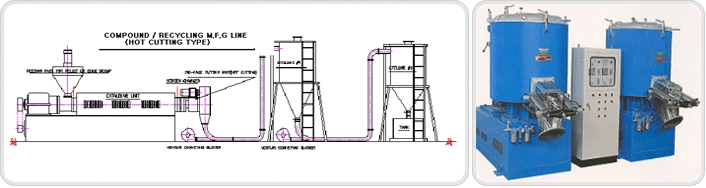

◎ Compounding and Pelletizing Manufacturing Line

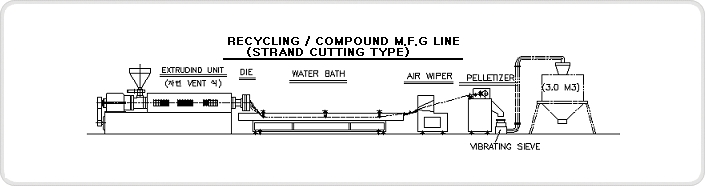

Available in all compound sizes and various extrusion out-put capacity, can supply with up to L/D ratio of 50:1. This long barrel enables vent ports and/or side feed ports to be incorporated. They are supplied with custom designed feed screws incorporating a variety of mixing sections for superior mixing ability. They are also available with vacuum venting, single or twin-screw, feeders to be provided for additives. Down stream units that can be equipped with Screen changers, Dies, Air wiper (Suction or Blowing), Cooling unit (water, air), Vibrated screen, Pelletizing Unit in type of 1) Strand cutting 2) Hot cutting 3) Under water cutting depending on Feeding materials, Final application and Out-put capacity.

◎ Reclaim and Recycling Pellet (chip) Generation Line

ShinKwang Co’s line of reclaim and recycling line is available from Ø30mm extruder and are custom-designed for the specific and bulk density material. We can provide a complete production line of double screw and single screw extruder recycling for Edge waste film, scrap foam/non-foamed film, sheet and Etc in processing type of 1) Hot-cutting and Air cooling 2) Strand cutting with cooled with water 3) Under water cutting. It’s consisting of Feeding unit of scrap or pellets to be palletized or chipped, Extruding unit with ventilation, Screen changer, Dies, Air wiper (Suction or Blowing), Cooling unit, Pelletizing unit, Vibrated screen, depending on raw materials, final applications and extrusion out-put capacity.

▶ Standard Specification

- Necessary to consult all of specification & performance with ShinKwang Eng.

- Extrusion out-put : 600kg/ Hr ( More higher available)

- Application materials : LD,LLD,PP,PS ( Foamed / Non-foamed), PET, ABS, PC,TPU, Etc.