This product is manufactured by

YANGHEON MACHINERY

This product is manufactured by

YANGHEON MACHINERY

Manufacturer information

YANGHEON MACHINERY

Index drive manufacturer, CAM, Mold and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

YANGHEON MACHINERY

Brand

-

SKU

717

Product Name

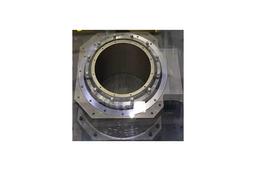

MOLD

Model Name

MOLD Series

Size

-

Weight

-

Product Details

Description

Gelatin Film is molded in turn by rotating of forming die rolls from both sides and a filling fluid is filled in by pump at the same time.

Once the fluid filled meets given amount, molding is completed.

Then the necessary heat for adhesion is transferred to gelatin film by segment to make the capsule adhered by the pressure of die rolls.

Completely interlocking of the die rolls and the pump never allow filling fluid lost and air coming in.

And the pump’s operational accuracy achieves the rate keeping the inequality of the filling amount within ±1%.

More products

Rotary Positioning&Indexing DrivesCFS Series

Zero-Backlash Positioning ReducersRH Series

Overload Protection DevicesCAT Series

Tilting IndexST Series

Rotary Positioning&Indexing DrivesCT Series

Rotary Positioning&Indexing DrivesCR Series

Overload Protection DevicesYF Series

Overload Protection DevicesYT Series

Pick & Place UnitsPP Series

Pick & Place UnitsFNH Series

Rotary Positioning&Indexing DrivesEU Series

Rotary Positioning&Indexing DrivesES Series

Rotary Positioning&Indexing DrivesCP Series

Zero-Backlash Positioning ReducersRG Series

Rotary TablesSC Series

1 / 4

Index drive manufacturer, CAM, Mold and more

Our company YANGHEON has reached the 24th year of its existence and mainly has designed and manufactured for INDEX DRIVE SYSTEM, CAM, CAPSULE MOLD and etc. in automatic engineering field.

Our mission is to design, manufacture, supply and develope automatic machines in Food, Pharmacy, TFT-LCD and Electric industries.

Our major sales items include Roller Gear Index, Parallel Index, Ring Type Index, Universal (Oscillating) Type Index, Barrel Index, P&P Unit, ATC (Automatic Tool Changer) Unit and custom Cam.

Our major goal is trying to do our best to product our best quality and receiving mutual credit with customers.

Komachine Inc.

Head Office:

Ace Dongbaek Tower 1-1101, 16-4,

Dongbaekjungang-ro 16beon-gil, Giheung-gu,

Yongin City, Gyeonggido, South Korea 17015

Branch Office:

606, Seoul Startup Center, 10,

Noryangjin-ro, Dongjak-gu, Seoul, South Korea 06938

CEOCharlie Park

Corporate #535-86-00664

ⓒ2025 Komachine Inc. All rights reserved.