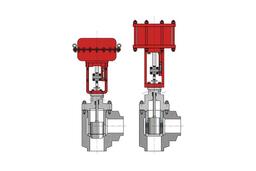

Single Port Unbalance Globe Valve

The S-Series range of Valves was developed to provide a cost effective, reliable and easily maintained control valve capable of working in rigorous environments.

The quick change trim option provides for easily accessible seat and trim components to minimise fitting and parts replacement times.

Stem guided contoured trim in both balanced and non balanced configuration gives excellent rigidity and resistance to vibration and service wear.

The valve is designed to accommodate other products within the BFS multi-hole multi stage and disk stack X[iks]-Trim

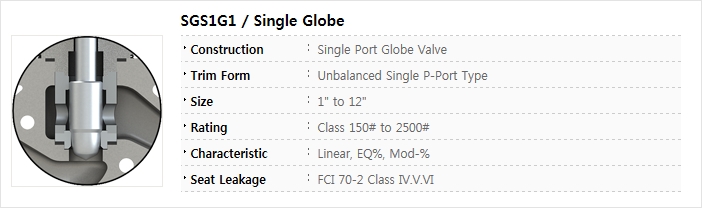

Cage Guided Balanced Valve / CG series

C-Series valves are supplied with either direct or reverse acting actuators plug a number of optional accessories to satisfy most final control element requirements.

Our C-Series valves also permits interchangeability of actuators and trim types within certain valve sizes for simplifying control changes in the field. This feature combined with a wide selection of standard and optional trim assemblies provides optimum control and has proven to be economical should field conversion be necessary.

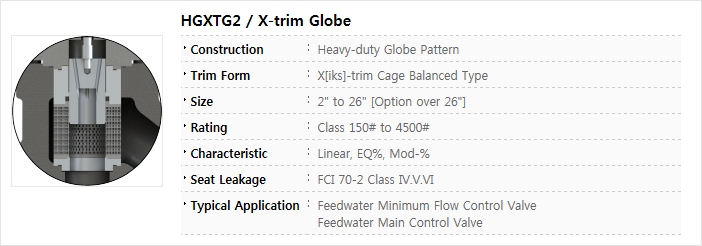

Heavy-duty Globe valve / HG series

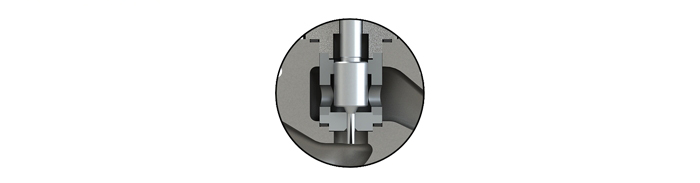

Auxiliary pilot plug Trim [APT]

- The APT trim is designed primarily for high pressure differential applications where tight shut-off is essential. Such applications include steam and water pressure reduction, steam throttling to atmosphere or to condenser, isolation, super-critical boiler start-up and variety of other uses in steam and water control system.

The design of the APT trim provides tight shut-off, excellent control and rangeability, but requires low actuator thrust which provides rapid response.

It is also lower in cost. The trim is basically a port throttling single seat design with main and pilot plugs working in APT.

The large main plug is the control device. Inside the main plug is the pilot plug connected rigidly to the valve stem, when closing the main plug seats first as a large balanced plug and this is rapidly followed by the closing of the pilot plug.

At this point, the plug from an unbalanced assembly and up stream pressure helps create high seating force resulting in reliable shut-off as high as class V. To open the actuator need only lift the small pilot plug to cause the main plug to once again become balanced.

All Teflon Body control valve / SF series

SF Series is designed for those applications where severe corrosion resistance is required. With its varied trim options and configurations, it is a most versatile valve for corrosive services, features include.

Micro Flow Control Valve / SG81 series

Increasing technical demands by user have persuaded BFS to rethink the standard approach to this specialized field of microflow control. Possible approaches and solutions were proposed and through the process of testing boty under laboratory and field conditions a new solution took from.

MCV are sesigned and manufactured for the express purpose of controll fractions of the capacity of flow through 1″and smaller line sized. The preference of the research facilities and process industries for scaled-down dimensions with proportionate economy in cost has been the prome factor in makin them available.

No omission has been made in paralleling the design, contruction and characteristics of performance, interchangeability or available accessories normally associated with larger valves.

MCV are the highest quality products available for low flow control and are well suited for those applications requiring precise control in very critical areas. The valves proven ability to function under the most adverse condition smakes it a vital tool in research and process as the final control element.

Cryogenic Service Control Valve / SG11 series

Reliability and ease of maintenance are essential features of any good control valve and to this end the BFS range of cryogenic service valves have beeen kept as simple as possible.

The number of components has been kept to a minimum and ease of access to the trim is straight forward through the removel of the bonnet retaining nut and lifting of the complete bonnet and plug assembly.

Bodies are normally suppliyed in stainless steel or bronze with a stainless steel extension of the suitable length for the installation position and temperature as low as munus 268℃(450℉). The extension can be fitted with a cold-box flange of any shape size required.

Trim construction is based on the tradifional BFS top & retainer guided quick change seat design and incorporates a soft seal in PTFE or RTFE when bubble tight shut-off is required. Other types of trim such as balanced, cage are availble when required. End connection can be flanged, screwd, soket or buttweld end plus pipe stabs as necessary. All body components are cleaned and degreased suitable for oxygen service and the end connection suitably masked after testing to prevent ingress of foreign matter, moisure.