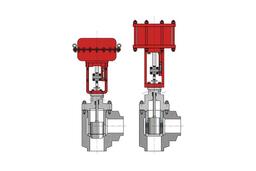

Triple offset Butterfly valve / TR series

TR Series valve utilises the well established unique valve geometry where the stem is offset from the body in two directions. And whilst the disc is a segment taken from a cone where the apex is offset form the center ling of the valve. The disc of the valve houses a field replaceable mental laminate seal whilst the field replaceable seat ring is housed in the body of the valve.

Bidirectional zero leakage is achieved by a unique principle in which the torque generated by the actuating mechanism is allowed to flex the metal seal within it's elastic limits, compressing the seal, thus ensuring that both seal and seat are perfectly matched. This seal resiliency results in zero leakage.

Double offset Butterfly valve / DR series

DR Series are designed to suit those severe conditions such as high temperature and high pressure which do not allow the use of rubber seated valves. High performance butterfly valves provide an economical, light weight, highly controllable process valve.

The design combines the tight shut off of the rubber lined type, and reduced torques and excellent throttling capabilities of the off-set disc assemblies, two types of seats, Meatal or teflon are available for uses in accordance with various applications.