PRINCIPLE OF SPRING ENERGIZED SEAL

S-E SEAL을 그랜드에 장치하면 스프링의 탄성에 의해 SEAL COVER의 LIP부위가 그랜드의 면에 눌리어 단단히 SEAL이 됩니다. 또한 유체의 압력에 의해 씰성이 높아집니다

Features

고정용과 운동용으로 사용합니다.

대부분의 화학약품과 유기용제에 사용 가능합니다.

-267℃의 극저온에서 340℃까지의 고온에 사용합니다.

고진공부터 고압까지 사용합니다.

종 유체에 대한 SEAL의 재질이 폭 넓게 마련되어 있습니다.

JIS B2406의 규격 및 AS568, DIN 규격에 의해 제작되며 특수 규격도 제작 가능합니다.

SEAL Type

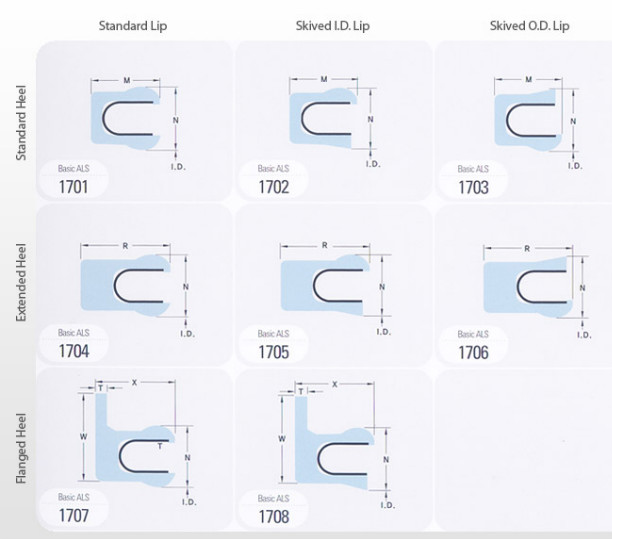

RADIAL SEAL(Reciprocating,Rotary) : ALS 1700

FACE SEAL(Static& Face Rotary) : ALS 1710

Main Use

| Gas turbine engine | VALVES PUMPS | Spaceship |

| PRESSSURE SWITCH | Rotary joint, SWEVEL JOINT | Medical, experimental equipments |

| Infrared rays system | ACTUATORS | ICE MAKERS |

| Petro-chemical plant | HPLC | Vacuum units |

| FILLING MACHINE | METERING | Food processing line |

| Tooling machine | Fuel control line for air plane | Plastic injection moulding machine |

| Hydraulic and pneumatic system for air plane | Extremely low temperature units and gasket |

ALS 1700

Description

ALS 1700 Seal is made of U type formed spring (CANTILEVR). So it has less load on the seal surface while getting bigger variance. Good for dynamicseal and it meets all standards of JIS B2406 (up to B3-P400).In addition, it is possible to produce the seal in cross section 19/mm

ALS 1710

Description

ALS 1710 seal is made of helical wound flat spring. It has high spring load property for static sealing of the spring and it is used for low and high speeddynamic seal.It has higher load property than that of ALS 1700 but it is more effective in thin liquids and gas sealing. ALS 1710 can use O-Ring optionally insteadof the spring.