시뮬레이션 소프트웨어 공급업체, 구조, 다물체 동역학, 음향/소음, 비선형, 복합재료 해석 등 시뮬레이션 분야

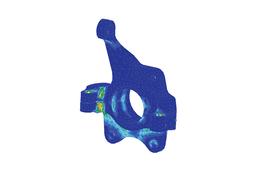

MSC Nastran은 선형 및 비선형의 전체 영역에 대해 정적, 동적, 열 해석을 수행하는 세계에서 가장 신뢰받는 구조해석 및 다분야 통합해석 솔버로, 자동화된 구조 최적화, 내장된 피로 내구해석 기능, 그리고 전체 해석 과정에 고성능의 다중 CPU 연산처리 기능을 제공합니다.

엔지니어는 MSC Nastran을 사용해 설계 대상이 기능과 안전을 확보할 수 있도록 강성, 강도, 수명을 보장해, 원하지 않는 상황(과도한 응력, 공진, 좌굴, 과도한 변형 등)이 발생하지 않도록 합니다. 또한 MSC Nastran은 구조적인 설계의 경제성 및 승객의 편안함을 향상시키기 위해 사용됩니다.

제조업체들은 제품의 개발 프로세스에서 MSC Nastran’s 독특한 다분야 통합 기능을 구조해석의 다양한 분야에 적용하고 있습니다.

MSC Nastran은 다음과 같은 분야에 사용될 수 있습니다.

- 설계 프로세스의 초기 단계에 가상 시제품을 적용함으로써, 전통적인 물리적 시제품 개발 방식에 비해서 획기적인 비용절감

- 제품의 서비스 상태에서 발생할 수 있는 구조 문제를 조기에 처리해 시간과 비용절감.

- 기존 제품에 대한 성능 최적화 또는 독특한 제품 차별화 개발로 경쟁력있는 상품 개발

MSC Nastran은 복잡하고 정교한 수치해석 방법에 기초하고 있으며, 가장 뛰어난 유한요소 기법으로 만들어진 솔버입니다. 비선형 유한요소 문제의 경우에도 내장된 내연적 또는 외연적 수치해석 기법으로 해석할 수 있습니다. 최적화의 경우, MSCADS와 IPOPT 등 여러 가지 최적화 기법이 제공됩니다. 또한 MSC Nastran 에는 nCode의 피로해석 솔버가 내장되어, 전체 과정의 일관 해석이 가능합니다.

MSC Nastran 기능:

Multidisciplinary Structural Analysis

Common structural analysis solutions are dedicated to one or a few analysis disciplines. To build up a comprehensive level of engineering analysis capability, multiple software solutions must be acquired, and users must be trained with each new tool. MSC Nastran features multiple analysis disciplines, enabling customers with one structural analysis solution for a wide variety of engineering problems.

- Use one platform to perform linear or nonlinear analysis for the following disciplines: static, dynamic (NVH & Acoustics included), thermal, and buckling, and reduce the dependency on multiple structural analysis programs from various vendors

- Perform fatigue analysis with embedded fatigue technologies and reduce the time usually associated with fatigue life determination

- Assess the behavior of advanced composites and fiber reinforced plastics with built in Progressive Failure Analysis and User Defined Services for Mean-field Homogenization coupling with Digimat

Customer Testimonial

"MSC’s integrated solution for linear and nonlinear calculations facilitates reuse of models which saves a lot of time in pre- processing and enables us to standardize the data exchange formats for body models when collaborating with other departments or external suppliers.”

- Sylvain Calmels, Manager

PSA Peugeot Citroën. PSA Peugeot Citroen Selects MSC Nastran as Its Choice for Nonlinear FEA.

"MSC Nastran is used to perform both linear and nonlinear stress analysis along with dynamic analysis for various components and sub-assemblies constituting the pump. […] Accurate predictions during these simulations is helping the C.R.I. Pumps' R&D team to reduce physical testing and product development time. The simulations are also enabling our engineers to analyze more design variants and come up with optimal designs, thus saving material cost too.”

- S. Ramdas, General Manager - Strategic Business Initiative

C.R.I. Pumps. C.R.I. Pumps Selects MSC Nastran for its Unique Linear & Nonlinear Integration.

Structural Assembly Modeling

One structural member is rarely analyzed independently. Structural systems consist of numerous components, and must be analyzed as a whole. MSC Nastran features a number of methods to join multiple components for system level structural analysis.

- Expedite meshing with Permanent Glue, enabling you to connect incongruent meshes that would traditionally require time consuming mesh transitions

- Save time constructing assemblies that consists of welds or fasteners via specialized connector elements

- Use "Modules" to combine and manage multiple components of a structure and form a complete assembly without the need to use additional connection elements or worry about the ID numbering schemes.

- Speed up the re-analysis of large assemblies by constructing Superelements, and optionally, share Superelements with other manufacturers while concealing confidential design information

- Perform contact analysis and determine contact stresses and contact regions in multi-component designs

- Increase productivity by using the Automatic Contact Generation feature to automatically create the contact bodies and define the contact relationship between them

Customer Testimonial

"The use of glued contact for assemblies reduces the problem setup time from 1 day to 1 hour and avoids tedious mesh alignment between parts.”

- Julien Rodess, Study Engineer Sogeti

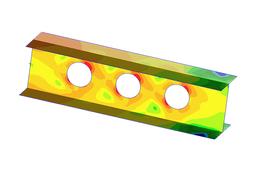

Automated Structural Optimization

Design optimization is a critical element in product development, but is often very iterative and requires a great deal of manual effort. MSC Nastran includes optimization algorithms that automatically seek optimal configurations in an allowed design space.

- Optimize for stress, mass, fatigue, etc. while varying design variables such as material properties, geometric dimensions, loads, etc.

- Enhance the shape or profile of structural members with shape optimization

- Find optimal composite laminate ply thicknesses with topometry optimization

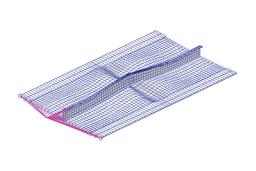

- Determine optimal bead or stamp patterns for sheet metal parts with topography optimization

- Remove excess and unnecessary volume with topology optimization

- Simultaneously optimize multiple models across disciplines with Multi Model Optimization

Customer Testimonial

"Advanced optimization processes are used on both component and system level to explore the design space in search of optimal designs. MSC.Nastran & Optimus software play herein an important role to capture the simulation process and accelerate the optimization schemes.”

- Dr. L. Cremers

BMW AG. Full vehicle early-phase concept optimization for premium NVH comfort at BMW.

High Performance Computing

Analysis models can be very large in size, requiring an extended period of time to solve. Such models can take hours or days to solve with traditional FEM applications. MSC Nastran features a number of High Performance Computing capabilities enabling engineers to solve large problems fast.

- Take advantage of multi-core and multi-node clusters with parallelization technologies: Shared Memory Parallel and Distributed Memory Parallel

- Accelerate simulation time and obtain higher performance for large models using the Automatic Solver Selection feature. MSC Nastran can automatically select the optimal solver and the most efficient parallelization method to use based on the analysis specifications (element types, solution type, available memory and etc).

- Utilize nVidia GPU Cards to accelerate the analysis of models composed of solid finite elements

- Perform modal analysis faster by using a highly tuned Lanczos solver or Automated Component Modal Synthesis

"Our ability to quickly and thoroughly evaluate many design alternatives made it possible to increase the processing speed of the machine by 50% while reducing vibration levels below the previous generation of machines. [...] The first prototype provided the performance and functionality predicted by the simulation so it became the final product. The new machine was completely designed in one and a half months, faster than any similar machine.”

- Stefano Grassi, Technical Director

Kosme. User Case Study - Kosme.

Customer Service

MSC Software provides a number of resources to support your use of MSC Nastran. Available services include:

- Technical support, often rated 4.5 out of 5 by customers.

- The MSC Learning Center, a subscription that entitles a user to the entire MSC Nastran training course catalog.

- MSC Nastran expertise, MSC Software was one of the original developers of the first NASTRAN code and has continuously developed MSC Nastran for over 40 years.

"Our MSC application engineer comes out at least once a month to see how we are doing and help us with any issues. In fact this plane would have been impossible to model without the phone support, on-site visits and consulting services provided by the MSC support team"

- Dana Taylor, AeroVironment.

Boeing, and GE Aviation. Global Services Brochure.