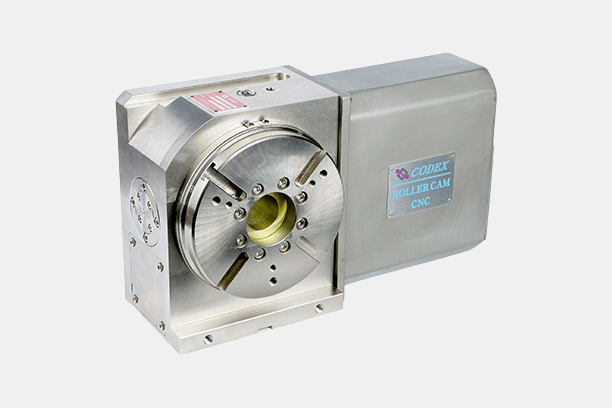

Overview & Features

Parallel Index Drive is designed in the Drive is designed in the way of combining the parallel cam of the input shaft and the turret of its output shaft in parallel. As one of plate cam units, it is a constraint cam and a conjugate cam that makes an intermittent motion in the way of transferring the roller of two cams.

The outline of the cam has the round of the dwell section and the mount shaped part along the cam curve. The two cams are combined differently in a sort of gear shape. Rotation occurs when the roller encounters the upper side.

There is a continuous curve line with the optimal displacement (S), velocity (V), and acceleration. Therefore, when rotary motion of the follower ends, the round part of the cam contacts the intercross-arrayed rollers to make a complete dwell. When the cam continues to rotate in this way, the follower makes the cycle of rotation-stop-rotation-stop repeatedly.

It is mainly applied to a small number of divisions (1N~8N). The Geneva drive gives fixed displacement angles for motion according to the number of divisions, whereas the parallel cam can provide a certain cam curve freely within a limited range. Since the roller is preloaded, it is possible to control backlash and vibration in transfer and at stop and there is no need of any additional brake at stop.

Features

Input shaft and output shaft are in parallel. Therefore, it can be used for the devices that fail to be driven by roller gear cam or barrel cam.

Excellent for conveyor driving

Conveyor driving using a small number of equally optimal

Conjugate cam- Parallel cam

Optimized to conveyor driving using a small number of divisions

Installation

Six sides are attachable.

Free design

Free design is supported, for a certain index angle and a certain cam curve are applied in a particular range.

Stability

Since the roller is preloaded, it is possible to control backlash and vibration in transfer and at stop and there is no need of any additional brake at stop.

Division methods of parallel cam

– 1 Dwell (1Cycle=move+stop=360°)

At each one rotation of input shaft, output shaft is moved one division (Fig.2).

Applied divisions: 1 division, 2 divisions, 3 divisions, 4 divisions

– 2 Dwell (2Cycle=move+stop+move+stop=360°)

At each 1/2 rotation of input shaft, output shaft is moved one division (Fig.3).

Applied divisions: 6 divisions, 8 divisions

| No | Category | Code | Description |

| a | Model | CF3 | Parallel Index Drive |

| b | Size | 200P | Size of index drive: the shaft distance between input and output: 200mm |

| c | No. of Stops | 01 | The number of stops per one rotation of output shaft; the number of divisions |

| d | Index angle | 21 | Input shaft’s rotation angle for one time (1 stop) indexing of output shaft: 210° |

| e | Cam curve | 2 | 1. Modified Trapezoid Curve (MT) 2: Modified Sine Curve (MS) 3: Modified Constant Velocity Curve (MCV) 4: Other curves |

| f | input/output Rotation direction | R |

|

| g | DWEL | 1 | The number of dwells |

| h | Direction of output shaft | 1 | Direction of output shaft, location relation of assembled input shaft, shape of output shaft

Direction of output shaft: 1-T, 2-U

Direction of input shaft: 1-T, 2-U, 3-T, U

Shape of output shaft: S-Standard L-Torque Limiter Attachment X-Special Shaft Type

|

| i | Direction of input shaft | 2 |

| j | Shape of output shaft | s |

| | | |

| | | 취부자세 및 유면계 위치를 지정(그림 예 : 13S를 기준으로 표시하였습니다.)

|

| Processing surface of attachment hole | |  -The processing surface of attachment hole for attaching index drive -The processing surface of attachment hole for attaching index drive

– An attachment hole follows standard; an attachment hole is processed on two sides of VW – If an attachment hole is also needed on R, S, T, and U sides, additional description is required. (※Full-sides processing – 6 sides are based on A.)

|

| Specially ordered specifications | | If there are specially orders specifications, write ‘X’. ※ Please attach the contents of special specifications separately ※ Please describe the changes in size, tolerance, specially ordered cam curve & index angle, specially ordered indexes, and oil level and drain change or settings. |