Power Generation Plant Parts Manufacturer, Mechanical Seal, Mechanical Packing, Seal, Gasket and more

PRINCIPLE OF SPRING ENERGIZED SEAL

Installing S-E Seal in the gland will become solid seal as the seal cover lip part is pressed by the gland surface because of the spring elasticity. Also, the sealing performance will get better due to the fluid pressure. (See the below picture.)

Features

For both static and dynamic seal

For most chemical products and organic solvent.

It can be used from extremely low temperature at -267˚C to high temperature up to 340˚C

Ranging from high vacuum to high pressure.

Wide ranges of seal materials for different fluids are available.

It is produced according to JIS B2406 standard and AS568 and DIN spec.

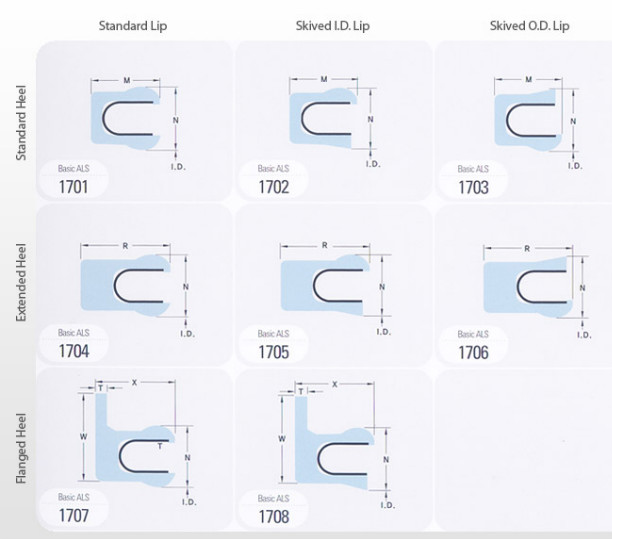

SEAL Type

RADIAL SEAL(Reciprocating,Rotary) : ALS 1700

FACE SEAL(Static& Face Rotary) : ALS 1710

Main Use

| Gas turbine engine | VALVES PUMPS | Spaceship |

| PRESSSURE SWITCH | Rotary joint, SWEVEL JOINT | Medical, experimental equipments |

| Infrared rays system | ACTUATORS | ICE MAKERS |

| Petro-chemical plant | HPLC | Vacuum units |

| FILLING MACHINE | METERING | Food processing line |

| Tooling machine | Fuel control line for air plane | Plastic injection moulding machine |

| Hydraulic and pneumatic system for air plane | Extremely low temperature units and gasket |

ALS 1700

Description

ALS 1700 Seal is made of U type formed spring (CANTILEVR). So it has less load on the seal surface while getting bigger variance. Good for dynamicseal and it meets all standards of JIS B2406 (up to B3-P400).In addition, it is possible to produce the seal in cross section 19/mm

ALS 1710

Description

ALS 1710 seal is made of helical wound flat spring. It has high spring load property for static sealing of the spring and it is used for low and high speeddynamic seal.It has higher load property than that of ALS 1700 but it is more effective in thin liquids and gas sealing. ALS 1710 can use O-Ring optionally insteadof the spring.