Blockage & Build Up Removal, Industrial Vacuum Cleaning, Conveyor Belt Optimisation and more

MACSYS WIRELESS

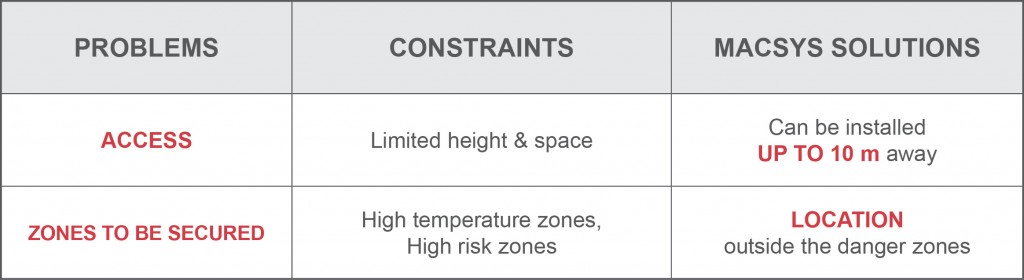

SOLUTION FOR SECURING AREAS WITH DIFFICULT ACCESS

+ SIMPLIFIED MAINTENANCE & AT MAN’S HEIGHT

CHARACTERISTICS OF THE MACSYS

- Number of heads 2 to 8

- Nominal outlet diameter of 100 to 150 mm

- Tank capacity of 200 L

- Reinforced metal or rubber flexible tubes

- 2 configurations available : Standard/ High temperature

> Our whole range of multi-head air cannons has been developed for wireless use

> All MACSYS hard wired installations can be converted into wireless.

IMPACT PRESSURE : Aerodynamics of the head/large capacity tank

FAIL-SAFE CONTROL : No MACSYS blast if there is a drop in air pressure

SAVINGS & MANAGEMENT : Same heads + spare parts & accessories as AIRCHOC®

QUALITY : Tank galvanized inside and outside/cast iron head/service life of over 30 years/reinforced frame

MAINTENANCE : Direct access to the mechanism/operation in degraded mode

RELIABILITY : Protected quick exhaust valve/self-aligning piston

INNOVATION : Reduced filling time/possibility of simultaneous blasts/adjustable heads

- Visits & technical recommendations (dimensioning & positioning)

- Supply of the installation plan

- Possible for us to assemble, supervise and commission the equipment

- Up to 3-year warranty

- In-house & external training (STANDARD INDUSTRIE training institute: IFSI – No. 31 59 05660 59)

- After-sales service & maintenance contract

- Statutory monitoring

DEFLECTORS : Directing the air flows towards sensitive clogging zones – Steel or refractory stainless steel version

AUTOMATIC AND CYCLICAL CONTROL DEVICES : Automatically trigger MACSYS blasts (controls up to 128 MACSYS)

INSULATOR : Secures maintenance operations: high temperature, aggressive products, risk of back flow of material

SAFETY DEVICE : Ensure the use and maintenance of MACSYS in complete safety (pressure gauge, pressure relief valve, shut-off valve etc.)

MAINTENANCE KIT : Reduces intervention time & simplifies inventory management

REMOTE CONTROL RAMP : Triggers MACSYS blasts remotely (centralised solenoid valves positioned about six feet off the ground)

PNEUMATIC DISTRIBUTOR : Activates MACSYS blasts pneumatically

CUSTOMER: Cement plant in Turkey

PROBLEM: Build ups in the riser ducts leading to production stops.

PRODUCT: Cement mills (future clinker and then cement)

OBJECTIVE: To remove the concretions that disrupt the industrial process and reduce the production capacity.

SOLUTION: Installation of 4 MACSYS Wireless : 2 MACSYS Wireless with 8 heads DN100 + 2 MACSYS Wireless with 5 heads DN100

RESULT: No more kiln shutdown related to the blockage of the riser ducts

CUSTOMER: Household Waste Incineration Plant (HWIP)

PROBLEM: Accumulation on the walls of the afterburner chamber which reduces the energy efficiency of the facility

PRODUCT: RPIFHW (Residues from the Purification of Incineration Fumes from Household Waste)

OBJECTIVE: Preventively eliminate the accumulation of RPIFHW on the walls

SOLUTION: Installation of 2 MACSYS Wireless 6 heads DN150

RESULT: No more disruption of the process. No more accumulation on the walls of the afterburner chamber equipped with MACSYS