This product is manufactured by

YOUNGJIN WORM

This product is manufactured by

YOUNGJIN WORM

Ball Screw Jack

Model Name

KOB

Data

Dimension table-YOUNGJIN WORM-Shaft lifting Type K0B

Manufacturer information

YOUNGJIN WORM

Precision Worm Reducer, Gantry Robot 3:1 Reducer, Dual Pitch Cavex Reducer, Dual Lead Worm, Screw Jack and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

YOUNGJIN WORM

Brand

-

SKU

142181

Product Name

Ball Screw Jack

Model Name

KOB, K1B, K2B, K3B, K4B, K5B, K6B, K6 1/2B, K7B

Size

-

Weight

-

Product Details

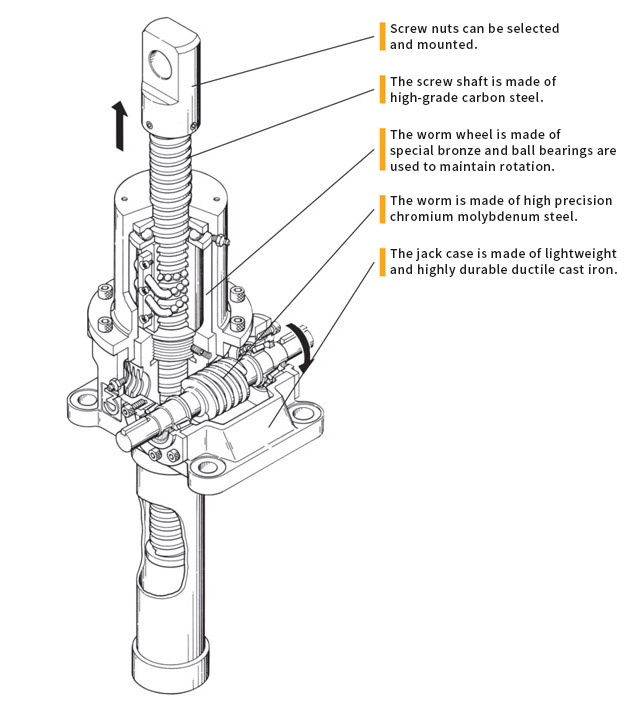

BALL SCREW JACK

It is a standard screw jack that utilizes the experience and technology that only specialized jack manufacturers can do.

- Since there is no rotational friction between the nut and the screw shaft like a ball bearing, compared to screw jacks using trapezoidal screws, the efficiency is about 3 times and it can be operated with low power.

- It generates little heat even when used at high speed, has low noise, and does not spill oil, so it is also suitable for pollution control.

- Since there is no self-locking function like the trapezoidal screw, install a brake if you need a self-locking function.

- There are abundant selection functions such as BELLOWS BOOT to protect the screw shaft, TRUNNION BASE, LIMIT SWITCH, and RC encoder for computer control.

Standard specification

| model number | KOB | K1B | K2B | K3B | K4B | |

| Basic Capacity (Tonf) | 1 | 2.5 | 5 | 10 | 20 | |

| Screw shaft diameter (mm) | 20 | 25 | 36 | 45 | 60 | |

| Screw shaft lead (mm) | 5(10) | 5(10) | 10 | 10 | 10(16) | |

| worm reduction ratio | H | 5 | 6 | 6 | 8 | 8 |

| L | 24 | 24 | 24 | 24 | 24 | |

| efficiency | H | 0.61 | 0.61 | 0.6 | 0.58 | 0.58 |

| L | 0.36 | 0.36 | 0.34 | 0.41 | 0.43 | |

| Maximum allowable torque per jack turn (kw) | 0.75 | 1.3 | 2.5 | 3.7 | 6 | |

| Required input torque for basic capacity (kgf-m) | H | 0.27 | 0.88 | 2.2 | 4.2 | 11 |

| L | 0.093 | 0.37 | 1 | 1.9 | 5 | |

| The number of revolutions of the worm for a stroke of 10 mm | H | 10 | 7.5 | 6 | 6.7 | 5 |

| L | 48 | 30 | 24 | 20 | 15 | |

| Holding Torque (kgf-m) | H | 0.15 | 0.5 | 1.3 | 2.1 | 5.6 |

| L | 0.018 | 0.07 | 0.15 | 0.35 | 1 | |

| Weight (kgf) In case of stroke 100mm | 5 | 11 | 20 | 40 | 70 | |

| Grease filling amount (kgf) | 0.15 | 0.6 | 0.9 | 1.5 | 3 | |

| Anti-rotation key torque (kgf-m) | 0.5 | 1.5 | 4.5 | 11.5 | 30 | |

| Input Shaft Allowable Overhang Load (kgf) | 30 | 45 | 70 | 120 | 120 | |

| Input shaft no-load torque (kgf-m) | 0.03 | 0.1 | 0.2 | 0.3 | 0.5 | |

| torque factor | H | 0.27 | 0.35 | 0.44 | 0.42 | 0.55 |

| L | 0.09 | 0.12 | 0.2 | 0.19 | 0.25 | |

| speed factor Stroke advance per 1 rotation of the input shaft mm |

H | 1 | 1.33 | 1.67 | 1.5 | 2 |

| L | 0.21 | 0.33 | 0.42 | 0.5 | 0.67 | |

| screw shaft forming | Rolling | Rolling | Rolling | Rolling | Rolling | |

| screw shaft cover material | Rigid Vinyl Chloride | Rigid Vinyl Chloride | Rigid Vinyl Chloride | Rigid Vinyl Chloride | Steel | |

| Operating temperature range (°C) | -15~+80 | -15~+80 | -15~+80 | -15~+80 | -15~+100 | |

| model number | K5B | K6B | K6 1/2B | K7B | |

| Basic Capacity (Tonf) | 30 | 50 | 75 | 100 | |

| Screw shaft diameter (mm) | 80 | 100 | 120 | 140 | |

| Screw shaft lead (mm) | 10(20) | 24 | 28 | 32 | |

| worm reduction ratio | H | 10 2/3 | 10 2/3 | 10 2/3 | 12 2/3 |

| L | 32 | 32 | 38 | 36 | |

| efficiency | H | 0.59 | 0.58 | 0.59 | 0.6 |

| L | 0.39 | 0.37 | 0.37 | 0.36 | |

| Maximum allowable torque per jack turn (kw) | 9.5 | 14 | 17 | 22 | |

| Required input torque for basic capacity (kgf-m) | H | 15 | 31 | 53 | 67 |

| L | 8 | 16 | 29 | 40 | |

| The number of revolutions of the worm for a stroke of 10 mm | H | 5.3 | 4.4 | 3.8 | 3.9 |

| L | 16 | 13.3 | 13.6 | 11.2 | |

| Holding Torque (kgf-m) | H | 8 | 16 | 18 | 37 |

| L | 0.9 | 1.4 | 1.5 | 2.1 | |

| Weight (kgf) In case of stroke 100mm | 130 | 270 | 500 | 750 | |

| Grease filling amount (kgf) | 4 | 6 | 8 | 12 | |

| Anti-rotation key torque (kgf-m) | 60 | 125 | 225 | 350 | |

| Input Shaft Allowable Overhang Load (kgf) | 220 | 250 | 250 | 300 | |

| Input shaft no-load torque (kgf-m) | 1 | 2 | 3 | 4 | |

| torque factor | H | 0.51 | 0.61 | 0.71 | 0.65 |

| L | 0.26 | 0.32 | 0.32 | 0.31 | |

| speed factor Stroke advance per 1 rotation of the input shaft mm |

H | 1.87 | 2.25 | 2.62 | 2.53 |

| L | 0.63 | 0.75 | 0.74 | 0.89 | |

| screw shaft forming | Rolling | Rolling | Machine Cutting | Machine Cutting | |

| screw shaft cover material | Steel | Steel | Steel | Steel | |

| Operating temperature range (°C) | -15~+100 | -15~+100 | -15~+100 | -15~+100 | |

More products

Small Ball Screw JackKSB

Small JackKSC

NUT lifting Ball Screw JackKOB, K1B, K2B, K3B, K4B, K5B, K6B, K6 1/2B, K7B

SCREW JACKKOC, K1C, K2C, K3C, K3 1/2C, K4A, K5A, K6A, K6 1/2A, K7A

Dual Lead Worm

NC-ROTARY TABLE용 듀얼리드웜SET

Dual Pitch Cavex Reducer

Gantry robot 3:1 reducer

Robot Flange

Dual output shaft

Single output shaft

Hollow Shaft Keyed

Hollow shaft-Shrink Disc

Hollow shaft-Shrink Disc

1 / 4

Precision Worm Reducer, Gantry Robot 3:1 Reducer, Dual Pitch Cavex Reducer, Dual Lead Worm, Screw Jack and more

YOUNGJIN WORM is a company specializing in the production of high-precision worm shafts and worm wheels contributing to the development of the best precision gear industry.

As a professional manufacturer of servo precision worm reducers (dual lead box), YOUNGJIN WORM is doing its best to contribute to the development of the precision gear industry in Korea with the experience and know-how accumulated for a long time. We are making ceaseless efforts to satisfy our customers in terms of quality, price, and delivery service with high-precision processing systems and the latest gear inspection equipment installed for achievement of the best efficiency. We will keep doing our utmost to become a first-class worm manufacturer by producing better products with superior information and technological power.We thank our customers for the unsparing guide and encouragement for our growth and development, and we look forward to the continuous use and participation of customers.

Komachine Inc.

Head Office:

Ace Dongbaek Tower 1-1101, 16-4,

Dongbaekjungang-ro 16beon-gil, Giheung-gu,

Yongin City, Gyeonggido, South Korea 17015

Branch Office:

606, Seoul Startup Center, 10,

Noryangjin-ro, Dongjak-gu, Seoul, South Korea 06938

CEOCharlie Park

Corporate #535-86-00664

ⓒ2025 Komachine Inc. All rights reserved.