LP Bypass Valve-Dump tube(Option)

The LP-TB valve uses multi-hole cage technology to provide system noise attenuation through frequency shifting is a proven method of noise attenuation recognized by ISA Technical Standard SP 75.07 and by the IEC in Technical Standard 544-8-3.

In frequency shifting the main flow stream is a separated into hundreds of tiny jets. The size of jets, which are primarily based on hole size, determine the resulting noise frequency-the smaller the size of the jet or multi-hole, the higher the frequency, which in turn produces a lower turns mitted dBA level. Multi-hole cage technology is ideally suited for intermediate pressure combined-cycle and low pressure drum boiler turbine bypass applications.

Unlike traditional multi-hole cage on the market today, the multi-hole trim uses over one thousand multi-holes spaced a part in a special pattern designed to ensure fill jet separation, structural intergrity, and maximum noise attenuation.

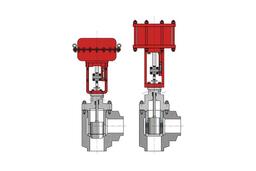

HP Bypass Valve / TBHP series

Steam pressure and flow are controlled by the position of the valve plug within the control cage.

A signal from the pressure control loop to the valve actuator moves the valve plug within the control cage to increase or decrease the amount of free flow area. The control cage has an array of calibrated orifices to provide the control characteristic specified. As the plug is lifted from the seat, steam is permitted to pass in to the center of the control X[iks]-trim cage and out through the seat ring.

The outlet section of the valve has a combination cooler and silencer section. As the steam leaves the seat ring, it enters a diffuser designed to further decrease steam pressure energy in a controlled-velocity expansion. Flow is directed radially through the multiple-path & Multi-turns Disk-Stack (X[iks]-trim) cage or multiple orifice cage diffuser, exiting in to the enlarged outlet pipe section. This section has been sized to accommodate the large change in specific volume associated with the pressure drop of the steam and to keep steam velocities within limits to control noise generation.

The outlet section is outfitted with a water supply manifold. The manifold (Multiple manifolds are also possible) provides cooling water flow to a number of individual spray nozzle installed in the pipe wall of the outlet section. The result is a fine spray mist injected in to the high turbulence of the radial steam flow. The combination of large surface are a contact of the water and high turbulence in the steam make a for very efficient mixing and almost immediate vaporization.

Single-variable Nozzle Steam Desuperheater / SNSD series

The bFS steam desuperheater SNSD consists of a tube shaped body with flange for bolting of the desuperheater to the insertion stud that is welded to the steam pipe. The water inlet is also flanged, at 90deg. angle to the desuperheater, to equipment service access.

The cooling water enters the inner nozzle chamber in the desuperheater through the flange. In the inner nozzle chamber the water is induced to fast rotation around the control plug by the special arrangement of the admission holes. The angle of the nozzle seat is slightly different from the nozzle holder so that the water velocity will accelerate the whole time and reach its maximum as it leaves the nozzle.

In order to maintain a constant pressure inside the injection nozzle, the latter is preloaded by a spring calibrated in function of the water/steam differential pressure.

Used for desuperheating of steam in small and medium sized pipes and is specially useful when the cooling water temperature is close to saturation.

Multiple-variable Nozzle Steam Desuperheater / MNSD series

The bFS steam desuperheater MNSD used in desuperheater applications where large spray water flows are required for cooling of the steam.

The MNSD is part of the steam line with a number of water atomizing nozzles, Variable Nozzles. The nozzles are connected to a common spray water pipe connection.

The spray water flow is controlled by a separate spray water control valve. A liner can be installed in the MNSD to improve the system turn down or protect the steam line.

The MNSD can easily be adapted for any special requirement, such as incorporation of separate emergency cooling arrangement or split range operation.

Cooling water Control valve Combined Steam Desuperheater / CCSD series

The CCSD series is designed to reduce steam temperature by the introduction of a coolant directly into the hot fluid to achieve contact desuperheating. The coolant is atomized as it passes under pressure through a series of spray nozzles which assists it in evaporating into the vapor and results in an increased quantity of vapor at the specified final temperature.