지금 보고 계신 제품의 제조사에요

한국엠에스씨소프트웨어(주)

구매정보

한국엠에스씨소프트웨어(주)

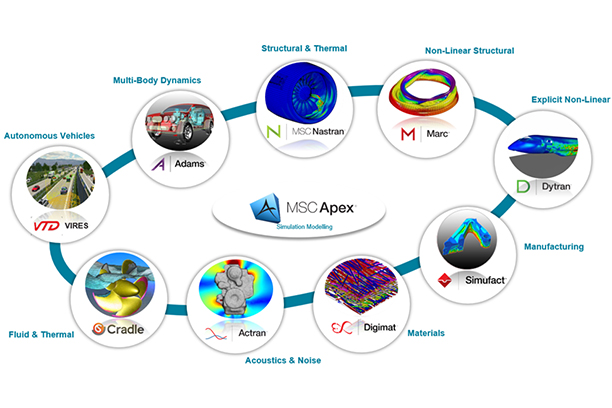

시뮬레이션 소프트웨어 공급업체, 구조, 다물체 동역학, 음향/소음, 비선형, 복합재료 해석 등 시뮬레이션 분야

연락처

031-719-4466

이메일

myhan@mscsoftware.co.kr

상품정보에 문제가 있나요?

정보수정 / 삭제요청

코머신은 제품 판매자가 아닙니다.법적고지 및 안내

제품 상세 정보

이 기업의 다른 제품

MSC NastranMSC Nastran Embedded Vibration Fatigue

MSC NastranMSC Nastran Embedded Fatigue

MSC NastranMSC Nastran Advanced Nonlinear Analysis

SimufactSimufact Welding

SimufactSimufact Forming

SimufactSimufact Additive

AdamsAdams Real Time

AdamsAdams MaxFlex

AdamsFlexible Multibody Systems in Adams

AdamsAdams Car

AdamsAdams Machinery

ActranActran VI

ActranActran DGM

ActranActran TM

ActranActran SEA

ActranActran for Trimmed Body

1/4