시뮬레이션 소프트웨어 공급업체, 구조, 다물체 동역학, 음향/소음, 비선형, 복합재료 해석 등 시뮬레이션 분야

제품 개발 사이클의 초기 단계에서 성능 및 효율의 설계 최적화, 재료비 절감

제품의 설계 및 개발 단계에서 엔지니어는 비용, 무게, 제조 가능성, 품질 및 성능의 각 분야에 대한 제품 특성 간의 균형을 고려해야 합니다. 이 때, 안전성과 같은 중요한 요소를 희생하지 않는 적절한 절충안을 찾아 최적 설계를 하기 위한 어려운 도전에 직면하게 됩니다.

MSC Software는 두께, 형상 및 위상 최적화 등 그라디언트(gradient) 기법의 사용 또는 및 응답 표면 기법에서 여러 해석 분야에 걸친 분석 및 최적화를 위한 다양한 프로세스 관리까지, 최적화에 필요한 모든 솔루션을 제공합니다. 이러한 솔루션은 고객이 타사 제품과의 연계를 필요로 하는 경우, 요구 사항에 맞게 조정할 수 있습니다.

MSC Software 제품은 다양한 설계 최적화에 사용되고 있다:

- 자동화된 외부 수퍼엘리먼트 최적화(AESO)

- Topography최적화를 통한 박판 구조물의 비드 최적화

- 실험 계획법(DOE) 및 보수적 불연속 설계(CDD)

- 등가 정하중 접근 방법

- 외부 계산 응답결과 반영

- 완전 응력 설계

- 최적화에 제조공정 제약조건 반영

- 복수 모델을 이용한 다분야 통합 최적화

- 비선형 응답 최적화

- Topometry를 이용한 최적두께 분포/자유크기 최적화

- 선형 및 비선형 도메인에서의 최적화

- 재료 물성 및 형상 크기등의 모델 파라메터의 최적화

- 파라메터 설계 및 해석

- 형상 최적화를 통한 응력 집중부위 감소

- 복합재를 위한 특화된 최적화

- 통계적 강건설계 접근

Gradient Based Optimization Methods

MSC provides proven solutions for component and system design optimization. Based on MSC Nastran’s gradient based optimization technique, the solutions can be broadly classified into three categories – namely, sizing, shape and topology optimization, depending on the methods employed in achieving the ideal design. By starting at a pre-specified point and searching the design space, a local optimal solution that satisfies the various constraints on the structural behavior is obtained, which can include advanced material properties for composites as variables in an optimization.

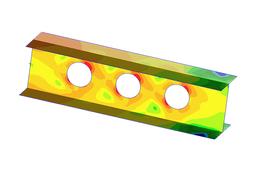

MSC also offers some advanced forms of shape and size optimization called topography and topometry, respectively, to give better control of material thickness and geometry as design variables. With response functions and constraints supported across multiple disciplines, users do not have to run multiple optimization runs for each discipline. It is possible to combine all these disciplines into a single run, users gain efficiency and obtain better designs.

Multi-run and Design Space Exploration

It is often desirable to develop a “best” design that is a good trade-off of multiple requirements and robust. This is where techniques like Design of Experiment (DOE) or Monte-Carlo (Stochastic) can be useful. MSC offers tools that allow users to setup multi-run CAE experiments based on multiple simulation models and even different disciplines; they can even include discrete design variables. A Response Surface Method (RSM) is used on the results from the experiment to create an approximate model, which represents how the design will behave over a large operating space. Once these models have been generated it becomes very easy and fast to perform “what if” and design trade-off studies.

Design Improvement Process Integration and Management

Optimization and Design Improvement studies can often be complex, requiring integration with third party specialty applications that may provide advanced capabilities for handling things like multiple design concepts or other specialty optimization and design improvement techniques. These studies also generate large amounts of simulation data and results associated with hundreds or even thousands of design variables and simulation models, which need to be tracked and managed.

MSC offers solutions that work well with other applications, providing capabilities that can play a customizable role in the process, which can even integrate and manage the entire process, as determined by the particular needs of the customer. Also, MSC’s simulation content and process management solutions are uniquely suited for keeping track of and managing the entire simulation process, ensuring that no relevant data is lost and critical design configurations are readily identifiable.

Related Products:

- Adams 다물체 동역학 시뮬레이션

- MSC Nastran 구조 & 다분야 통합 해석

- MSC Nastran Desktop 데스크탑용 다분야 통합 해석 소프트웨어

- Patran FEA 솔버를 위한 Pre/Post 솔루션