시뮬레이션 소프트웨어 공급업체, 구조, 다물체 동역학, 음향/소음, 비선형, 복합재료 해석 등 시뮬레이션 분야

다분야 통합 진동소음 해석을 통한 제품의 진동 및 음향특성 향상

많은 제품에서 구조 진동은 문제를 발생시키는 원인이 될 수 있습니다. 그것은 피로와 내구 문제를 유발할 수도 있고, 사용자나 주변의 사람들에게 원하지 않는 진동으로 느껴지거나 들리게 되어 불편한 반응을 초래할 수도 있습니다. 또한, 의도치 않는 구조진동은 제품의 작동을 방해하고, 안전에 있어 불안 요소로 발전할 가능성도 있습니다.

NVH (소음, 진동, 거칠기) 또는 N&V (소음 및 진동)은 제품의 품질을 직접적으로 결정짓는 중요한 요소중의 하나입니다. 따라서 경쟁 제품과의 차별화를 위해 제품 개발팀이 성능에 대한 목표 다음으로 가장 중시하는 것 중 하나입니다.

MSC의 선도적인 FEA 및 MBD(다물체 동역학) 솔버의 기능을 통해, 설계자는 다양한 작동 조건 하에서 부품이나 시스템이 어떻게 진동할 것인지 시뮬레이션하고 예측할 수 있습니다. 예를 들면, 승용차의 운전자나 승객이 도로 주행을 할 때, 정속 주행 또는 가속 주행 상태에서 어떠한 엔진소리를 듣게 될지, 도로의 움푹한 곳을 통과할 때 발생되는 진동의 느낌과 소음이 어떠할지 등에 대해 시뮬레이션 할 수 있습니다.

MSC Software 제품은 다양한 소음 및 진동 해석에 사용되고 있습니다:

- 판넬의 음향 모우드 기여도 분석

- 트림바디 모델 해석

- 자동화된 부품모우드 중첩법(ACMS)

- 복소수 고유진동수

- 동적 설계최적화

- 다물체 동역학 해석을 위한 탄성체 구조물

- 주파수 응답 해석

- 주파수 응답 함수(FRF)

- FRF방식이 합성법(FBA)

- 전달 경로 해석 (TPA)

- 하중 정의

- 하중들: 주파수 연동 또는 시간 연동의 힘, 변위, 속도, 가속도

- 모우드 기여도

- 복수 모델 및 다분야 통합 최적화

- 고유진동 해석

- 랜덤 응답 해석

- 수퍼엘리먼트

- 과도 응답 해석

산업체 적용사례:

- Aerospace & Defense: 항공 음향/ 팬 소음, 실내 소음, 엔진 흡차음재, 구조 감쇄 시스템.

- Automotive: 변속기, 배기계, 브레이크, 위성기어, 체인 구동계, 카울 환기 판넬, 엔진, 엔진 마운트, 변속기 마운트, 후방 액슬 탄성체, 전방 액슬 탄성체.

- Heavy Equipment: 미끄럼 제어기, 점탄성 마운트, 파이프 완충 시스템, 차량동력학 및 샤시, 캡 완충장치.

Structural Vibrations

APPLIED IMPULSE LOADING FOR A TIME NVH ANALYSIS

ATV VIBRATION ANALYSIS

Understanding the structural vibration characteristics of a component or system typically requires the engineer to understand both the natural vibration characteristics of the structure, also known as vibration modes, and how the structure responds to external loading factors, typically referred to frequency response and transient loading.

MSC’s NVH solutions provide capabilities for linear and non-linear modal, transient and frequency response analyses for structural components, systems and mechanical assemblies. When noise or durability are a concern, this vibration information can then be used to perform coupled acoustics predictions for interior or exterior noise, or it can be used to perform product fatigue predictions, using the detailed, vibratory and transient loading histories obtained in the vibration simulation.

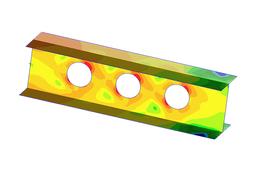

ACOUSTIC ANALYSIS OF A MUFFLER

ACOUSTIC RADIATION ANALYSIS OF AN ENGINE

INTERIOR ACOUSTICS EXAMPLE

MSC offers proven solutions and techniques for simulating and predicting what are typically called internal and external acoustics.

For intenal acoustics MSC provides a coupled Fluid-Structure Interaction simulation which calculates the pressure inside a bounded domain. This is used to solve for sound pressure levels experienced by the occupants. For exterior acoustics, the solution provides a structural vibration coupling with exterior acoustics simulation techniques. This capability is used to analyze the sound field radiated by a vibrating structure in a single coupled vibro-acoustic analysis.

With the use of infinite elements, the need for large meshes of the field around acoustic sources is eliminated. In addition to the sound pressure level calculations, MSC provides analysis techniques that allow the engineer to identify which components in an assembly are contributing the most to a particular noise, something referred to as panel participation.

FRF BASED APPROACH USED TO ANALYZE ENGINE AND TIRE LOADS

A typical challenge in NVH analysis is identifying the path of energy flow from source to a point of interest.

It is beneficial to understand the source of undesired vibration or noise well in advance of vehicle assembly. MSC provides a Frequency Response Function (FRF) based methodology to help address this need.

FRF represents the frequency response of components due to unit loads at a given frequency. The FRFs of components can then be combined to yield the FRFs of assemblies of these components. An advantage of this approach is that it lends itself to transfer path analysis (TPA). Through TPA, users can trace the energy flow from source to receiver. This allows identification of critical paths and noise sources. For instance, in the top left picture, the source of noise is the engine and in the bottom picture, the noise source is due to tire loads. Thus, to understand and improve vehicle NVH, it is necessary that the engineer perform a full system analysis, and MSC Nastran enables this with its scalable, application specific solvers.

Large Model and Assembly Simulation

CONNECTORS ARE SPECIFIED BETWEEN THE TRIM BODY AND THE SUSPENSION AT FOUR LOCATIONS

Critical NVH characteristics, those observed and perceived by the user or bystander, are more often than not related to the design of the entire vehicle.

In order to simulate these behaviors, the simulation model must represent a nearly complete vehicle system, which can lead to very large computer models of the structural and mechanical system assemblies. MSC offers industry proven, high performance methodologies to correctly and efficiently model and simulate these types of models. This includes:

- Techniques for correctly modeling welded, glued, and fastened assemblies, as well as jointed connections.

- ACMS – Automated Component Mode Synthesis for faster, parallelized modal analysis of large models

- External Superelements for use in assembly process to enable logical partitioning of a full-vehicle and reuse of component information.

Related Products:

- Actran Acoustics 강력한 음향 시뮬레이션 소프트웨어

- Adams 다물체 동역학 시뮬레이션

- Marc 고급 비선형 시뮬레이션 솔루션

- MSC Nastran 구조 & 다분야 통합 해석

- MSC Nastran Desktop 데스크탑용 다분야 통합 해석 소프트웨어

- Patran FEA 솔버를 위한 Pre/Post 솔루션

- SimDesigner CAD 내장형 통합 해석

- SimXpert 다분야 통합 시뮬레이션 솔루션