Stirweld Friction Stir Welding machine

-Stirweld expands its range of products: after a friction stir welding head for CNC machine, a FSW spindle for robot and FSW tools we are proud to announce the availability of a complete solution: our friction stir welding machine with a HAAS or Doosan CNC machine and a Stirweld FSW head.

-With our complete Friction Stir Welding equipment, you can add a new know-how to your machine park in a simple way thanks to Stirweld’s support and at a controlled cost.

|

STIRWELD FSW MACHINE ADVANTAGES A COMPLETE FRICTION STIR WELDING SOLUTION -A single point of contact for the implementation of a complete, autonomous, and operational FSW system 2 MACHINES IN 1 -Machining and welding in the same machine EASY FSW TRAINING -Simplified handling of the Stirweld FSW machine compared to dedicated Friction Stir Welding machine EXCELLENT PRICE FOR VALUE -Stirweld Friction Stir Welding machine represents a very good compromise between modularity and efficiency STIRWELD FSW SUPPORT -Stirweld manages FSW training and the after-sales service

|

|

STIRWELD FSW MACHINE CHARACTERISTICS

Stirweld offer you two FSW complete machine solutions to implement friction stir welding in your machine park:

-Friction Stir Welding machine H15-01

-Friction Stir Welding machine D11-01

FSW MACHINE H15-01

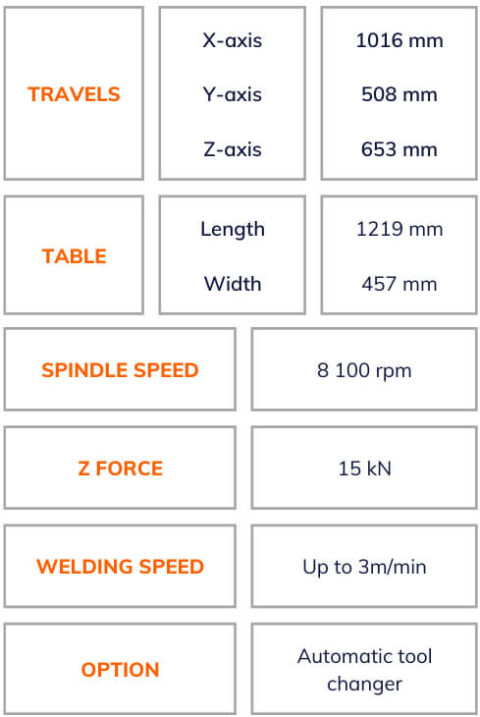

-This Stirweld Friction Stir Welding machine is based on a HAAS VF-3.

Features of Stirweld FSW machine H15-01

-The FSW Stirweld H15-01 has a thrust force of 15 kN and can therefore weld up to 10mm thick in a single pass and up to 18mm in a double pass. This is therefore suitable for the mass production of automotive foundries, for the welding of liquid cold plates, mounting brackets, busbars and stiffened panels.

-The FSW Stirweld machine features air and water cooling, a welding speed of 3m/min and a rotation speed of 8100 rpm. It also has integrated force control for optimised production monitoring of the friction stir welding operation.

-As an option, Stirweld’s milling add-on allows you to switch from welding to machining in and back again. Also, you can choose to add a 4th axis in option.

-An important benefit of the Stirweld Friction Stir Welding machine is a very low maintenance machine with a high lifetime. It is the best compromise between modularity and efficiency for your machine park.

FSW MACHINE D11-01

-This Stirweld Friction Stir Welding machine is based on a DOOSAN DNM 750L.

Features of Stirweld FSW machine D11-01

-The D11-01 FSW Stirweld allows you to weld all types of applications such as heat sinks for e-mobility, rigid panels or cold plates thanks to its 11kN thrust force, its 12,000-rpm speed and its 2160×760 mm table.

-For an optimal friction stir welding operation, the FSW Stirweld machine is equipped with an air- and water-cooling system.

-To go further, Stirweld offers you the possibility to install a milling add-on to your machine in order to switch from machining to welding in an instant. Moreover, it is possible to add a 4th axis.

-Like every Stirweld product, the Friction Stir Welding machine D11-01 requires very little maintenance and is very durable.