Multidiscipline Simulation Software Supplier, Linear and Nonlinear Finite Element Analysis (FEA), Control Systems Simulation and more

Maximize Nonlinear Flexibility in Multibody Dynamics Simulations

The Need for Higher Fidelity Simulations

Greater emphasis has been placed in recent years on high-speed, lightweight, precise mechanical systems. Often, these systems will contain one or more structural components for which deformation effects are paramount for design analysis. In those cases, including the flexibility for those key components results in a more precise loading prediction and improved system performance prediction.

Traditional Approaches to Flexible Bodies in Adams:

Adams Flex has been used by Adams users for many years to include linear flexibility into multibody dynamics systems, and allows one to capture relatively small deformation of flexible components (up to roughly 10% of the characteristic length) during a simulation.

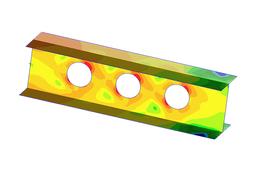

However, when it comes to components with geometric or material nonlinearity, like the twist beam in a suspension system or engine mounts, Adams Flex does not provide the capability to cope with nonlinearity in the simulation.

Hence, to incorporate the nonlinear flexibility into multibody dynamics systems, we have introduced a new methodology/tool for our users – MaxFlex.

MaxFlex allows for the representation of geometric nonlinearity (i.e., large deformations), material nonlinearity, and boundary condition nonlinearity. It is based on implicit nonlinear finite element analysis.

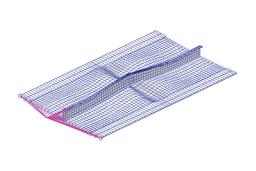

Model provided by Volvo Cars

Here're some of the highlights for MaxFlex:

Using Adams MaxFlex, an MBD analyst can increase model accuracy by including nonlinear structural behavior

It's a streamlined workflow, similar to Adams Flex

Simulation is conducted entirely in Adams

There is shared memory parallel (SMP) support to increase simulation efficiency

Easy to set up models and run simulations

No third-party tool is needed to generate animations with both rigid and nonlinear flexible parts, since it can be done in Adams/Postprocessor

MaxFlex workflow

We see potential use of MaxFlex in durability events, where permanent deformation of suspension components alters the load path and loads which we were not capturing using mnf bodies. Having this capability in MBD environment would help us in generating more realistic loads earlier in the program,” Chandra Tangella, Loads Analysis Engineer at FCA