Multidiscipline Simulation Software Supplier, Linear and Nonlinear Finite Element Analysis (FEA), Control Systems Simulation and more

Advanced Nonlinear Simulation Solution

Simulate products more accurately with the industry’s leading nonlinear FEA solver technology

Marc is a powerful, general-purpose, nonlinear finite element analysis solution to accurately simulate the product behavior under static, dynamic and multi-physics loading scenarios. Marc's versatility in modeling nonlinear material behaviors and transient environmental conditions makes it ideal to solve your complex design problems.

Marc is ideal for product manufacturers looking for a robust nonlinear solution. It has capabilities to elegantly simulate all kinds of nonlinearities, namely geometric, material and boundary condition nonlinearity, including contact. It is also the only commercial solution that has robust manufacturing simulation and product testing simulation capabilities, with the ability to predict damage, failure and crack propagation. Combined with its multi-physics capabilities that help you couple thermal, electrical, magnetic and structural analyses, Marc is the complete solution that can address all your nonlinear simulation requirements.

Nonlinear and Multiphysics Solution

Marc, optimized for nonlinear analysis, delivers comprehensive, robust solution schemes to solve problems spanning the entire product lifespan, including manufacturing process simulation, design performance analysis, service load performance and failure analysis. These include:

- Nonlinear analysis that incorporates all forms of nonlinearities (Material, geometric, boundary condition including contact)

- Thermal analysis

- Coupled thermomechanical analysis

- Electromagnetics

- Piezoelectric analysis

- Electrical-Thermal-Mechanical

- Electrostatics and Magnetostatics coupled with structural response

- Manufacturing processes like sheet metal forming, hydroforming, extrusion, blow molding, welding, induction heating, quenching, curing, cutting etc.

- Piezoelectric analysis with higher order 3D elements

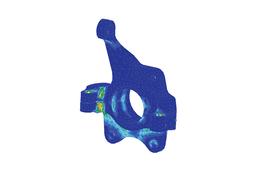

Contact Analysis

Investigate interaction between multiple components with Marc’s superior and intuitive contact modeling capability.

- Set up a contact model easily in 1-D, 2-D or 3-D, analyze and visualize the ever-changing component interaction.

- Gain modeling efficiency by avoiding the need for additional contact elements, contact pairs or slave-master definitions.

- Set up and investigate self-contact without additional modeling effort.

- Analyze effects of friction and related material changes with ease.

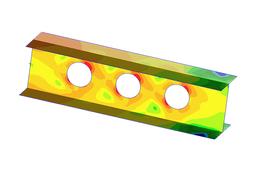

Nonlinear Materials

Choose from an extensive library of metallic and non-metallic material models, and a collection of over 200 elements for structural, thermal, multiphysics and fluid analyses to accurately model the materials used in your designs.

- Isotropic, orthotropic and anisotropic elasticity

- Isotropic and anisotropic plasticity

- Hyperelasticity (elastomeric materials)

- Time-dependent and time-independent behavior

- Powder metals, soils, concrete, shape memory alloys

- Solder, viscoplasticity, creep

- Composites

- Piezoelectricity

- User defined material models

Failure and Damage

Select from a comprehensive set of failure models to study degradation and failure of metals, concrete, composites, and elastomers.

- Ductile damage

- Damage accumulation in elastomers

- Composite failure analysis

- Laminate bond failure

- Low tension cracking and crushing

- Fracture mechanics

- Crack propagation under monotonous, low cycle and high cycle loads

- User defined failure models

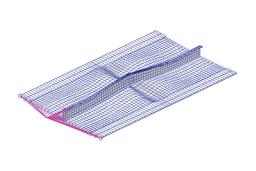

Automatic Remeshing

Achieve higher accuracy with less modeling effort with the help of automatic remeshing schemes that ensure high mesh quality in large deformation problems.

- Automatic remeshing for 2D and 3D models

- User specified criteria for mesh controls

- Beneficial to manufacturing process simulations and self-contact analyses