Rotary damper, Voltex tube, Air cooling machine, Air knife, Stopper cylinder, Buffer, In line filter

Vortex Air Cooling Oil Jets

1. Vortex Air Cooling Oil Jet (Vortex Air Lubrication Cooling Mist Jet) does not use the conventional (Solenoid Valve, motor control method) It uses compressed air in the factory to protect the tooling, precision machining, and environment. It is a great product that mist-cools both products and tools at the same time. It can also be used for mist-spraying lubricants of any viscosity using the vortex tube cold air and the oil-flow spray of an oil venture-type, venture-type, and is excellent for cutting machining, and lubricating mist spray. It discharges cold air from a vortex tube, degrees Max-30 ° C (minus 30 ° C). immediately cools the oil Also, cutting the oil mist immediately cools the oil by spraying lubricant mist. It is an effective product that protects machining tools and maintains high-quality processed products. by spraying lubricant mist. It is an effective product that protects machining tools and maintains high-quality processed products.

2. Vortex Air Cooling Oil Jet products improve the roughness of the works and protects tools.

3. Vortex tube cooler cools oils immediately by spraying mist to bring about the benefit of tool protection and is effective in improving the quality of products. It also brings about a savings effect.

4. It is a safe product that protects the environment. It is safe from explosion and is not interfered with by RF/EMI frequency and electronics).

5. It is configured to adjust the amount and angle of oil mist with an Adjust Knob Ring.

Vortex Air Cooling Oil Jet Advantages

- No Freon

- No Electricity

- No Maintenance

- Quiet Operation

- Environment

- Safety

- No moving parts

- Instant On and Off

- No Solenoid Valve

- M.Q.L method(minimum lubrication process injection) Minimum Quantity Lubrication

Mini Vortex Tube (7 CFM)

| Model | Descripton |

|---|---|

| SMVAOJ-007M-LU1 | Mini Vortex 7 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method, Flex Nozzle, Magnet Base |

| Model | Inlet Pressure(bar) | Air Consumption (ℓ/min) |

Outlet Air Capacity Min-Max (ℓ/min) |

The lowest temperature (℃) |

|---|---|---|---|---|

| SMVAOJ-007M-LU1 | 4 | 120-130 | 120-120 | -24 |

| 5 | 160-170 | 160-120(이하) | -25 | |

| 6 | 200-210 | 185-135 | -27 | |

| 7 | 235-245 | 215-160 | -32.8 |

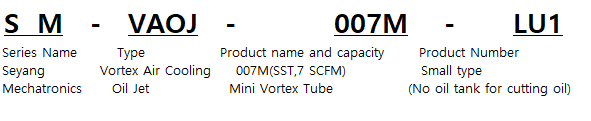

Type Nomenclature

Vortex Hexagon Tubes (7CFM, 8CFM, 10CFM, 15CFM, 25CFM, 35CFM)

| Model | Description |

|---|---|

| SMVAOJ-007M-HEX-LU2 | Vortex Hexagon 7 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method, Flex Nozzle, Magnet Base |

| SMVAOJ-008M-HEX-LU2 | Vortex Hexagon 8 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method, Flex Nozzle, Magnet Base |

| SMVAOJ-010M-HEX-LU2 | Vortex Hexagon 10 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method, Flex Nozzle, Magnet Base |

| SMVAOJ-015M-HEX-LU2 | Vortex Hexagon 15 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method, Flex Nozzle, Magnet Base |

| SMVAOJ-025M-HEX-LU2 | Vortex Hexagon 25 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method, Flex Nozzle, Magnet Base |

| SMVAOJ-035M-HEX-LU2 | Vortex Hexagon 35 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method, Flex Nozzle, Magnet Base |

| Model | Inlet Pressure(bar) | Air Consumption (ℓ/min) |

Outlet Air Capacity Min-Max (ℓ/min) |

The lowest temperature (℃) |

|---|---|---|---|---|

| SMVAOJ-007M-HEX-LU2 | 4 | 170 | 110-170 | -10 |

| 5 | 205 | 185-205 | -16 | |

| 6 | 250 | 215-250 | -19 | |

| 7 | 300 | 260-300 | -20 | |

| SMVAOJ-008M-HEX-LU2 | 4 | 255 | 110-115 | -17 |

| 5 | 340 | 115-120 | -19 | |

| 6 | 430 | 120-123 | -21 | |

| 7 | 500 | 465-125 | -23 | |

| SMVAOJ-010M-HEX-LU2 | 4 | 290 | 280-118 | -15 |

| 5 | 370 | 370-120 | -20 | |

| 6 | 460 | 450-160 | -23 | |

| 7 | 520 | 550-210 | -25 | |

| SMVAOJ-015M-HEX-LU2 | 4 | 280 | 275-120 | -15 |

| 5 | 380 | 345-130 | -20 | |

| 6 | 460 | 440-185 | -22 | |

| 7 | 520 | 485-210 | -26 | |

| SMVAOJ-025M-HEX-LU2 | 4 | 300 | 300-123 | -19 |

| 5 | 380 | 390-175 | -22 | |

| 6 | 450 | 450-230 | -25 | |

| 7 | 520 | 505-270 | -30 | |

| SMVAOJ-035M-HEX-LU2 | 4 | 300 | 295-140 | -19 |

| 5 | 400 | 390-195 | -23 | |

| 6 | 470 | 460-250 | -28 | |

| 7 | 540 | 525-300 | -32 |

Type Nomenclature

Vortex Tubes (7CFM,8CFM,10CFM,15CFM,25CFM,35CFM)

| Model | Description |

|---|---|

| SMVAOJ-007M-LU3 | Vortex Tube 7 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method cutting oil Tank(1L),Flex Nozzle, Magnet Base |

| SMVAOJ-008M-LU3 | Vortex Tube 8 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method cutting oil Tank(1L),Flex Nozzle, Magnet Base |

| SMVAOJ-010M-LU3 | Vortex Tube 10 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method cutting oil Tank(1L),Flex Nozzle, Magnet Base |

| SMVAOJ-015M-LU3 | Vortex Tube 15 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method cutting oil Tank(1L),Flex Nozzle, Magnet Base |

| SMVAOJ-025M-LU3 | Vortex Tube 25 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method cutting oil Tank(1L),Flex Nozzle, Magnet Base |

| SMVAOJ-035M-LU3 | Vortex Tube 35 SCFM, Stainless Steel, Case(Aluminum), No power, oil mist spray, M,Q,L method cutting oil Tank(1L),Flex Nozzle, Magnet Base |

| Model | Inlet Pressure(bar) | Air Consumption (ℓ/min) |

Outlet Air Capacity Min-Max (ℓ/min) |

The lowest temperature (℃) |

|---|---|---|---|---|

| SMVAOJ-007M-LU3 | 4 | 170 | 110-170 | -10 |

| 5 | 205 | 185-205 | -16 | |

| 6 | 250 | 215-250 | -19 | |

| 7 | 300 | 260-300 | -20 | |

| SMVAOJ-008M-LU3 | 4 | 255 | 110-115 | -17 |

| 5 | 340 | 115-120 | -19 | |

| 6 | 430 | 120-123 | -21 | |

| 7 | 500 | 465-125 | -23 | |

| SMVAOJ-010M-LU3 | 4 | 290 | 280-118 | -15 |

| 5 | 370 | 370-120 | -20 | |

| 6 | 460 | 450-160 | -23 | |

| 7 | 520 | 550-210 | -25 | |

| SMVAOJ-015M-LU3 | 4 | 280 | 275-120 | -15 |

| 5 | 380 | 345-130 | -20 | |

| 6 | 460 | 440-185 | -22 | |

| 7 | 520 | 485-210 | -26 | |

| SMVAOJ-025M-LU3 | 4 | 300 | 300-123 | -19 |

| 5 | 380 | 390-175 | -22 | |

| 6 | 450 | 450-230 | -25 | |

| 7 | 520 | 505-270 | -30 | |

| SMVAOJ-035M-LU3 | 4 | 300 | 295-140 | -19 |

| 5 | 400 | 390-195 | -23 | |

| 6 | 470 | 460-250 | -28 | |

| 7 | 540 | 525-300 | -32 |

Type Nomenclature

Type Nomenclature

Vortex Air Cooling Oil Jet Dimensions

M.Q.L (Minimum Quantity Lubrication)

Mist M.Q.L Nozzles

Features

In order to machine-process the metal, we use coolants that meet the conditions of the material.

Cutting oil is essential for cooling, lubrication, rust prevention, and in the protection of machining tools. However, there are various problems such as harm to the body, degradation of the working environment, and environmental pollution during oil disposal and disposal costs.

Vortex air cooling lubrication mist jet complements these problems and does not require electricity and emits cold air by using a compressed in through Vortex tube to perform MQL (Minimum Quantity Lubrication) to cool lubricants. It is different than the Work Piece cooling method in that you spray mist to cool specific areas. It offers a larger ranger of viscosity and can precisely control the quantity of oil mist depending on the conditions of the process.

Vortex Air Cooling Oil Jet is also an effective product for protecting tools, extending tool’s life, and shortening production cycle-time. The pressure can be used from Min 3.5 bars to Max 17 bars on the secondary gauge pressure supplied to the Vortex Tube. Please use (Flow Control Valves) to adjust the flow rate supplied to the Vortex Tube.

The cold air supplied to the Vortex Tube offers cold air lubrication mist according to pressure and flow rate.

Please observe the instructions for installation and operation according to the product environment.

Vortex Air Cooling Oil Jet Works

Applications

- Mold processing

- Plastic piercing and punching

- CNC processing machine

- Acrylic cutting

- Spindle aluminum processing

- Engraving machining

- Woodworking machine

- Drilling

- Circular saw

- CNC milling

- Band top

- Cutting/Cutting

- End mill

- Tapping

- Boring brooch

- Face cutter

- NC spindle

Advantages

- Pneumatic principle without electricity

- Improves industrial process

- Preserves cutting oil at room temperature in an oil tank during winter seasons

- Decrease tool wear and maintain precision while processing

- Eliminates the cause of cutting oil deterioration

- Eliminates jumping ups due to the rotation of the machining tool or due to smear and spreading of cutting oil

- The surrounding environment stays pleasant

- Eliminates the problem of oil disposal

- Productivity increases at low cost and work simplification

- Safe to work with magnets, easy to attach and detach.

- Minimizes oil consumption with mist-spraying

- Immediate control during use with On/Off

Warning

Vortex Air Cooling Jet Lubrication mist system is for industrial use. Do not use on commercial vehicles.

Precautions for use

- Do not use the Vortex Air Cooling Oil Jet when the installation capacity is insufficient.The

- Vortex Air Cooling Oil Jet lubrication system is applicable only for industrial use and can be used based on technical data.

- Do not change the structure of the Vortex Air Cooling Oil Jet lubrication system. We will not be held responsible for damage incurred from such actions.

- If the installation capacity is insufficient or exceeds the proper capacity, compressed air will increase, which may cause the compressed air to become exhausted.

- Do not use mist spray of cold air on the human body.

- When installing Vortex Air Cooling Oil Jet, always install cutting oil and lubricant on top after setting the location to attach the magnet.

- Aim and spray the cooling/hot outlet of the product toward the product to be used.

- Do not discharge or spray the cool/hot outlet toward people and avoid contact. It may result in fatal injuries.

- Installation of the Vortex Air Cooling Oil Jet Lubrication System requires action from the field person and the person in charge of the machine first.

- After shutting off the air under the direction of the person in charge of the field and machinery, adjust the position of the cooling nozzle to the cooling area and start your work.

- If spraying of mist oil or water does not work, do not inhale through the mouth. Follow the instructions of the person in charge of the field or machinery.

Precautions on operating environment

- It is recommended to use in a machine where the air an and cleaning system is configured.

- It is recommended to use clean, dry compressed air in the supplied air line, and an air filter of 5μm or less is recommended for the removal of solid residuals

- Do not use it under high pressure.

- In case of spraying Cool / Heat Nozzle mist, please attach a silencer to the cool/warm air outlet if it is noisy. (Please contact our sales department)