Test equipment manufacturer, Automotive parts testing, Performance testing, Reliability testing, Durability testing

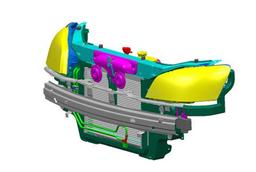

The Brake Performance Test System will be used for the performance of friction, wear and overheating of the brake disc, pad and shoes (components of brakes used in the railway vehicles) in accordance with relative international standards.

Intelligence electric brake test system (IMEB) : The system is designed for testing the intelligence electric brake to analyze the characteristic of performance and durability. It could be test as the operating, functional, durability, and environment tests with an environment chamber.

The GAF testing system is for measuring the axle load which is generated at a half-shaft during the driving of a vehicle.

To measure and analyze the axle load, the system can test a half shaft by changing the test condition such as rotating speed, torque, and angle.

Electric pedal test system : The system is designed for simulation of the operating brake pedal with by an actuator which has similar function of driver’s foot.

Depend on the test method, the booster angle and position could be adjustable.

In addition, the caliper angle and height also could be adjustable.

The system is to verify the reliability (Distributing characteristic, Stiffness, Leakage) of the booster & cylinder assembly (Brake components).

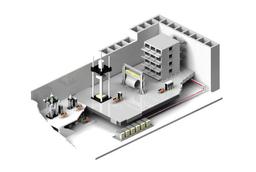

Booster test system : the system is designed for testing the brake

booster assembly to analyze the characteristic.

In addition, through the durability test, it could calculate the life time and find the problem its result. By using an environment chamber, it could test various temperature condition.

The GAF testing system is for measuring the axle load which is generated at a half-shaft during the driving of a vehicle.

To measure and analyze the axle load, the system can test a half shaft by changing the test condition such as rotating speed, torque, and angle.