Test equipment manufacturer, Automotive parts testing, Performance testing, Reliability testing, Durability testing

The high speed wheel & rail contact simulation system is to analyze and measure all the matters between wheel and rail contact surface during the high speed rotation.

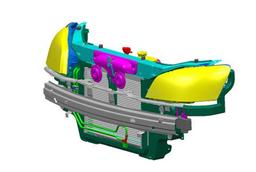

The system is organized by the main frame, wheel & rail disk specimen, wheel & rail driving motor, radial & thrust load actuator, contact angle & attack angle adjuster, EMG brake, environmental chamber, main control system, sensors, and etc.

There are various test can be done by this system such as rolling contact test (RCF test), adhesive strength test, wear test, etc. from subway to high speed train. In addition, the system has environmental simulation equipment of water, oil, wind, sand insertion with temperature control (-30℃~80℃).

This testing system is to investigate the properties of a rail vehicle influences train behavior after one of the wheelsets has derailed.

A mathematical model and natural experiment were carried out to investigate accelerations and displacements on

the train body after the derailment.

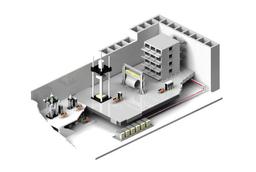

This is a 1/5 scaled testing equipment system to analyze stability of a bogie and wheelset.

This system is composed of main frame, driven roller, hydraulic actuator, and controller. It is used to compare dynamic model prediction with scaled bogie simulator.

Our versatile arrays of components, accessories, and application software allow you to build your own cost-effective testing systems.

KNR offers the tools and consults your needs to meet the test requirements for all kinds of vehicle and rail components.

The Brake Performance Test System will be used for the performance of friction, wear and overheating of the brake disc, pad and shoes (components of brakes used in the railway vehicles) in accordance with relative international standards.