Test equipment manufacturer, Automotive parts testing, Performance testing, Reliability testing, Durability testing

With a load capacity from 2 kN to 300 kN, the SiMat 1000 Series opens up new mechanical-testing applications in electronic and medical product development and basic research.

It’s static and dynamic capabilities make the SiMat 1000 Series ideal for monotonic, durability, and fatigue testing.

SiMat 2000 Series perform everything from simple strength testing to dynamic characterization of structures to comprehensive fracture and fatigue testing.

They can accommodate an incredibly wide range of specimens, including metal components, civil structures, construction materials, geomaterials and components for aerospace, oil and gas pipeline, rail, wind turbines and more.

These load frames can be combined with performance-driven hydraulics packages, advanced controls and application software, and a variety of accessories to create a high-force solution that meets your exact specifications.

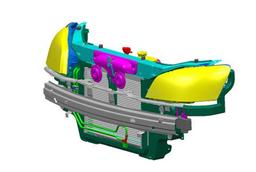

SiMat 3000’s Dynamic characterization involves the application of one or more forces at various frequencies, as a means of determining how the properties of an elastomer or rubber material or component changes in a dynamic environment. Dynamic properties measured can include K*, phase, E*, tan delta, energy, and damping coefficient.

Test results are typically input into computer models for validation purposes.

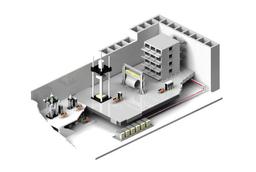

SiMat 4000 Series are used to evaluate the mechanical and physical properties and performance of materials, structures and components through static, cycle and block loading.

The design of our products will be uncompromising with respect to the quality of the test data, the safety of personnel and the long-term value to our customers.

SiMat5000 series the evaluation of rock, concrete and asphalt binder properties requires special testing and extremely stable temperatures. Test types include tension, fatigue, compression, impact and hardness compression.

CF (Corrosion Fatigue) Testing System provides a economical method for long-term creep and stress rupture testing applications of metallic materials in accordance with ASTM and other similar international testing standards.