Test equipment manufacturer, Automotive parts testing, Performance testing, Reliability testing, Durability testing

We are currently developing a robot which can perform NDE (non-destructive examination) inside a pipe while moving through the pipe itself. Pipe inspection robots have to be able to travel through vertical pipes, pipe elbows, and pipe intersections, while standing up to the environment inside the pipe and pulling a heavy non-destructive testing module.

KNR is working in consortium with KOGAS on the project ‘8″ and 16″ Unpiggable Gas Pipe Self-Propelled NDE Robotic Technology Development’. KNR is responsible for the portion of the research that deals with robotics, while KOGAS heads up the entire project. The current issue is developing technology that allows a wireless robot to travel through a pipe in use at 50 bar of gas pressure, withstand the inner environment of the pipe, and overcome the obstacles in the pipe while performing NDE tests. PIBOT (Pipe Inspection roBOT), the module that handles these tasks, is a series of connected joints that moves through the pipe with a slithering motion, like a snake. This project is still in development.

Fluidized Reduction Furnace Gas Duct Cleaning Robot

(Harsh Environment Operation Mobile Robot)

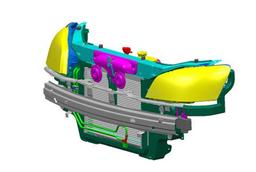

The fluidized reduction furnace gas duct cleaning robot is a mobile robot similar to Gibbon in a way that it operates in an environment difficult for a person to access due to high temperature and poisonous gas.

Designed to remove reduced iron (instantaneous temperature of 600℃) in a form of sedimentary high temperature dusts from a 25m long gas duct in a given period of time, dustproof and cooling was critically considered in order for robot to continuously operate in a dusty environment of 90℃. The robot has various operating modes. At the end-effector of the robot, a Bucket or an Air Suction Tool can be attached to collect dusts in the dump or directly remove via suction.

The system was downsized using mHPU(4-modules) as the hydraulic power source and can be remotely controlled by a wireless controller. Several cameras and lights are integrated into the system in order to visually monitor the operating environment inside the duct and various sensor systems are included to track the position and location of the robot. Also, different control modes such as torque control for emergent situations like collision and automated drive are possible.

– Project supported by POSCO.

Hydraulic servomechanisms and demanding applications such as military robots have led to increasing interest. Motivated by Big-dog in US, KNR has joined a four-legged robot project and developed all four legs of the walking robot with hydraulic actuators.

Because the legs of field robots need enough torque to be able to support the weight of the robot and move the robot, hydraulic actuators are an excellent fit. KNR teamed up with KITECH in the development of the Korean quadruped robot ‘Jinpoong’. KNR designed the actuators and legs for the field robot, which also increased the possibility of KNR’s actuators being used in defense. KNR provided optimized designs for leg modules by combined use of linear and rotary actuators to drive the multi-leg robot. KNR is also part of a consortium with Hyundai Motors and Hyundai Rotem which manages the research and development ‘Hydraulic Wearable Robot’ project. In that project, KNR is currently developing actuators and other components for the upper- and lower-body sections of the robot, and is also developing the upper-body structure. This research can be beneficial for developing other various walking robots. Much of the research is still ongoing, and there are opportunities for a wide variety of applications.

So called wearable robots are announced a lot in the paper and news. As a member of power enhancement robot project, KNR has designed upper body of wearable robot and tested last two years. Each arm handles 20kgf load.

A robot’s operational efficiency is most emphasized in the environments where humans cannot reach.

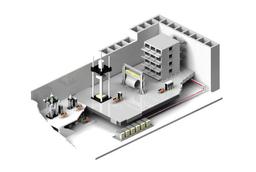

Gibbon, developed with KHNP in 2016, is a mobile hydraulic manipulator based robot that can safely and freely relocate and retrieve hazardous objects in harsh conditions.

The mobile platform of Gibbon has four independently controlled wheels with suspension and can drive in various terrains. The manipulator uses 4-module mHPU (Mobile Hydraulic Power Unit), which increases the mobility of the overall system. Both the mobile platform and the manipulator are built light weight so that a person can lift each components. The comprehensive system is also remotely controlled, providing easy control for the user.