This product is manufactured by

NUMALLIANCE

This product is manufactured by

NUMALLIANCE

CNC Wire Bending Machine Robomac TF

Model Name

R106TF G4

Data

카탈로그-누말리언스-CNC 와이어 벤딩 기계 로보맥 TF

Manufacturer information

NUMALLIANCE

Verified & Trusted Manufacturer

Providers of Turnkey Productivity Solutions for Cold Forming Metal Wire, Tube, and Flat-stock

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

NUMALLIANCE

Product Type

Machine

Brand

-

SKU

136598

Product Name

CNC Wire Bending Machine Robomac TF

Model Name

R106TF G4, R108TF G4, R206TF G4, R208TF G4, R210TF G4, R213TF G4, R214TF G4, R216TF G4, R310TF G4

Size

-

Weight

-

Product Details

Range : Sequential machines

Technical Presentation of the wire bending machine Robomac TF

Main features

|

Man / Machine Interface

|

| R106TF G4 | R108TF G4 | R206TF G4 | R208TF G4 | R210TF G4 | R213TF G4 | R214TF G4 | R216TF G4 | R310TF G4 | |

|---|---|---|---|---|---|---|---|---|---|

| Wire capacity up to 600 N/mm² | From 2 to 6,35 mm | From 2,5 to 8 mm | From 2 to 6,35 mm | From 2,5 to 8 mm | From 3 to 10 mm | From 4 to 13 mm | From 4 to 14 mm | From 5 to 16 mm | From 3 to 10 mm |

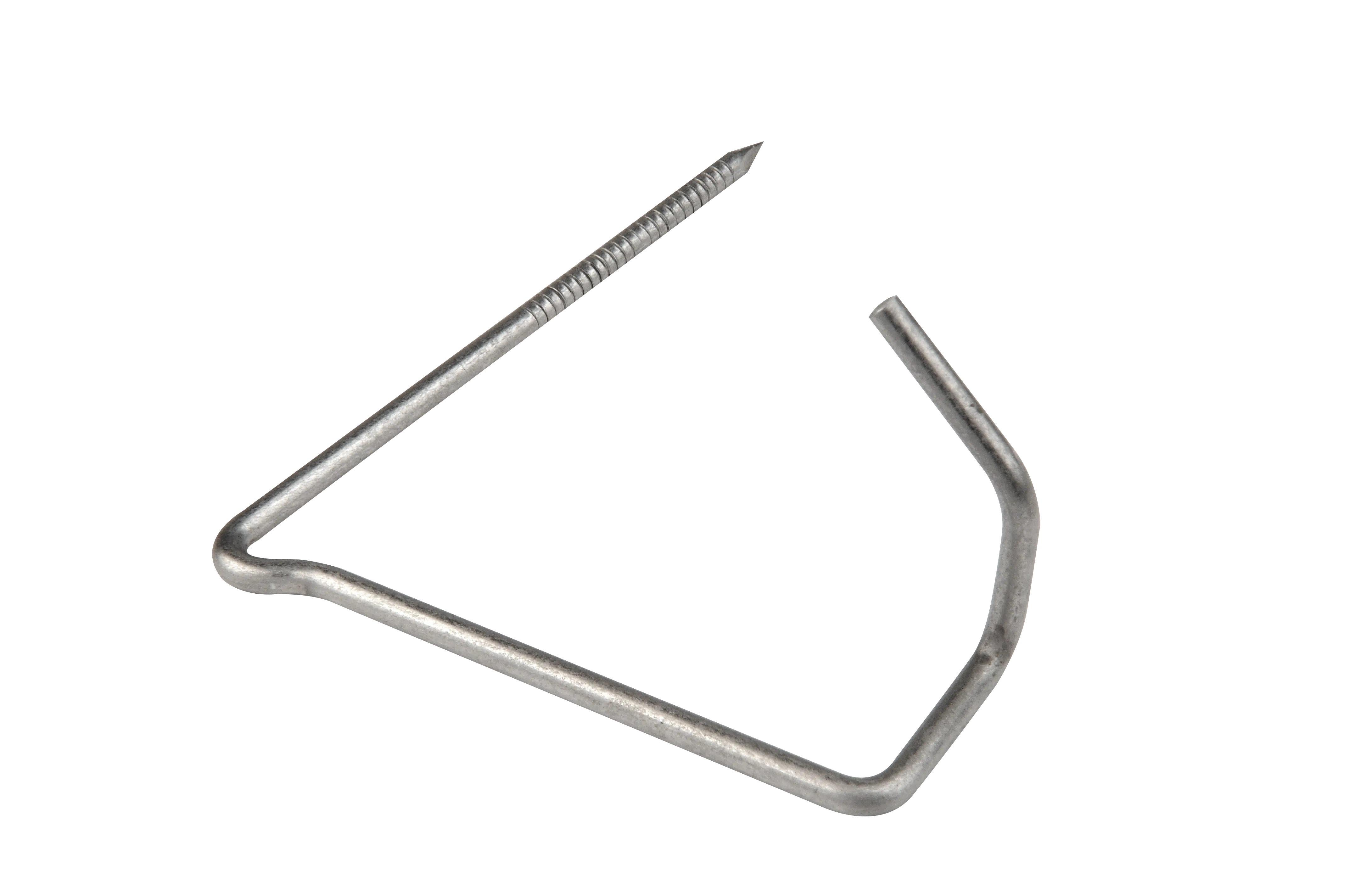

Example of parts made with the wire bending machine Robomac TF

More products

CNC Spring Forming Machine FRXFRX04, FRX06

CNC Bending Machine FTXFTX08 G4, FTX10 G4, FTX13 G4, FTX 13 G8, FTX 14 G8, FTX16 G8

CNC Wire Bending Machine Robomac 2 HeadsR2104TF, R2105TF, R2106TF, R2108TF, R2110TF, R2112TF

CNC Wire Cutting Machine NumacutNUMACUT W05, NUMACUT W08, NUMACUT W12

CNC Bending Machine FTXFTX08 G4, FTX10 G4, FTX13 G4, FTX 13 G8, FTX 14 G8, FTX16 G8

Robomac TFER213TF G4, R214TF G8, R216TF G8

Standard Hydraulic Pressh-P100, h-P200

CNC Bender NumabendT815

CNC Flat Stock Bender FPXFPX Series

CNC FPX BusbarFPX Busbar

CNC Automatic Wire Bender R4xxR4 Series

CNC Strip Bending Machine NumastripNumastrip

CNC Pipe Bending Machine NumatubeNumatube 80

Eaton Leonard VB SMALLVB 19 ELEC

Numacell FTR

1 / 4

Providers of Turnkey Productivity Solutions for Cold Forming Metal Wire, Tube, and Flat-stock

Founded in 1986, NUMALLIANCE Group is one of the leading providers of turnkey productivity solutions for cold-forming metal wire, tube, and flat-stock. The company has developed its know-how far beyond bending. Numalliance solutions can also integrate secondary operations such as notching, cutting, punching, chamfering, welding, threading, embossing, robotization, thermal stabilization, 3D control, and auto-correction of resulting programs.

All of Numalliance’s automated production machines and cells are designed and manufactured in France (6), and in North America: USA (Lebanon, Ohio) and Mexico (Querétaro).

Our solutions are sold around the world, banking on its 11 subsidiaries and technical sales offices (USA, Mexico, China, India, Russia, Slovakia, Germany, Brazil, Romania) and its network of 40 agents. Therefore they meet the expectations of all types of sectors: automotive, aeronautics, agriculture, construction, sanitary, furniture, medical, shop equipment, and more!

The company Numalliance accompanies its customers all around the world and offers them a reactive and attentive service.

Numalliance’s innovative solutions are recognized worldwide for their quality, accuracy, productivity and flexibility.

Bring a whole new dimension to your production and make your factory a showcase for Industry 4.0! At Numalliance, our Research and development team is constantly developing ever more efficient tools. Thanks to the integration of our digital solutions and equipment such as robots or AGVs, we will bring speed and precision to the production of your parts. Always to improve your productivity, while guaranteeing ease of use, Numalliance will be able to assist you in making your factory a showcase for Industry 4.0, at the cutting edge of the latest technologies.

Komachine Inc.

Head Office:

Ace Dongbaek Tower 1-1101, 16-4,

Dongbaekjungang-ro 16beon-gil, Giheung-gu,

Yongin City, Gyeonggido, South Korea 17015

Branch Office:

606, Seoul Startup Center, 10,

Noryangjin-ro, Dongjak-gu, Seoul, South Korea 06938

CEOCharlie Park

Corporate #535-86-00664

ⓒ2025 Komachine Inc. All rights reserved.