Non-woven fabric machine manufacturer, Needle punching machine & molding machine

• Working Width : 3400~6000mm

• Needle Beam Stroke / Max stroke frequency - 30mm / 1100 s/min

- 40mm / 1000 s/min

- 60mm / 800 s/min

• Needle per Liner meter : 2000, 3000, 4000, 4500, 5000

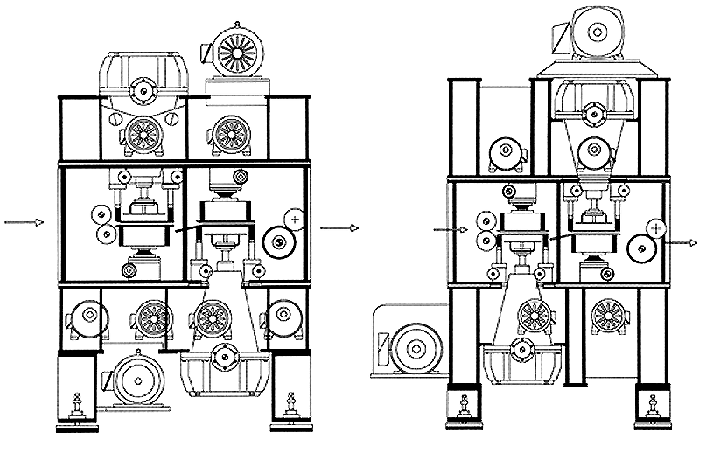

▶ Machine Structure

• The needle beam is divided into three or four upper and lower piece. These pieces of needle beam connected to the module boxes are designed to be operated up and down by separate driving motors.

• In a narrow space, one machine can give high working capacity and efficiency which are equal to those of two units (DR type and UR type).

• However, the machine may have a little vibration caused by two driving motors.

• The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

• The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

▶ Motors

• Two variable speed AC-inverter (or DC motor) with 50HP(37kw) are used as main motor. They may vary depending on work load.

• A variable speed AC-inverter (or DC motor) with at least 2HP(1.5kw) is used as inlet and outlet motors.