Non-woven fabric machine manufacturer, Needle punching machine & molding machine

• Working Width : 2400~3000mm

• Needle Beam Stroke / Max stroke frequency - 30mm / 1200 s/min

- 40mm / 1100 s/min

- 60mm / 900 s/min

• Needle per Liner meter : 2000, 3000, 4000, 4500, 5000

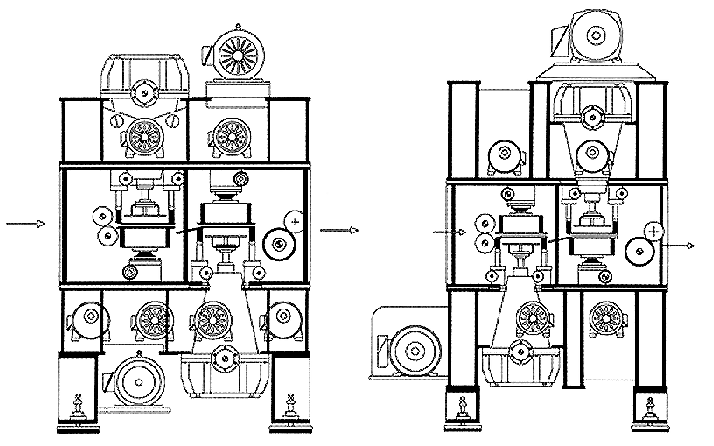

▶ Machine Structure

• The needle beam is divided into a upper piece and a lower piece. These pieces of needle beam connected to two upper and lower module boxes are designed to be operated up and down by separate driving motors.

• In a narrow space, one machine can give high working capacity and efficiency which are equal to those of two units (DR type and UR type).

• However, the machine may have a little vibration caused by two driving motors.

• The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

• The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

▶ Motors

• Two variable speed AC-inverter (or DC motor) with 30HP(22kw) are used as main motor. They may vary depending on work load.

• A variable speed AC-inverter (or DC motor) with at least 1HP(0.75kw) is used as inlet and outlet motors.